- 300% reduction in cleaning cycles

- 98% First Pass Yield

- 67% Increase in production efficiency

- 32% increase in transfer efficiency on Micro BGA Component

- 20% Increase in solder paste volume yield

- 18% Increase in units produced per hour

- 15% Reduction in consumables

- 13% Reduction in identified defects

- 10% Better paste release

- Reduced Scrap Rate to de minimis

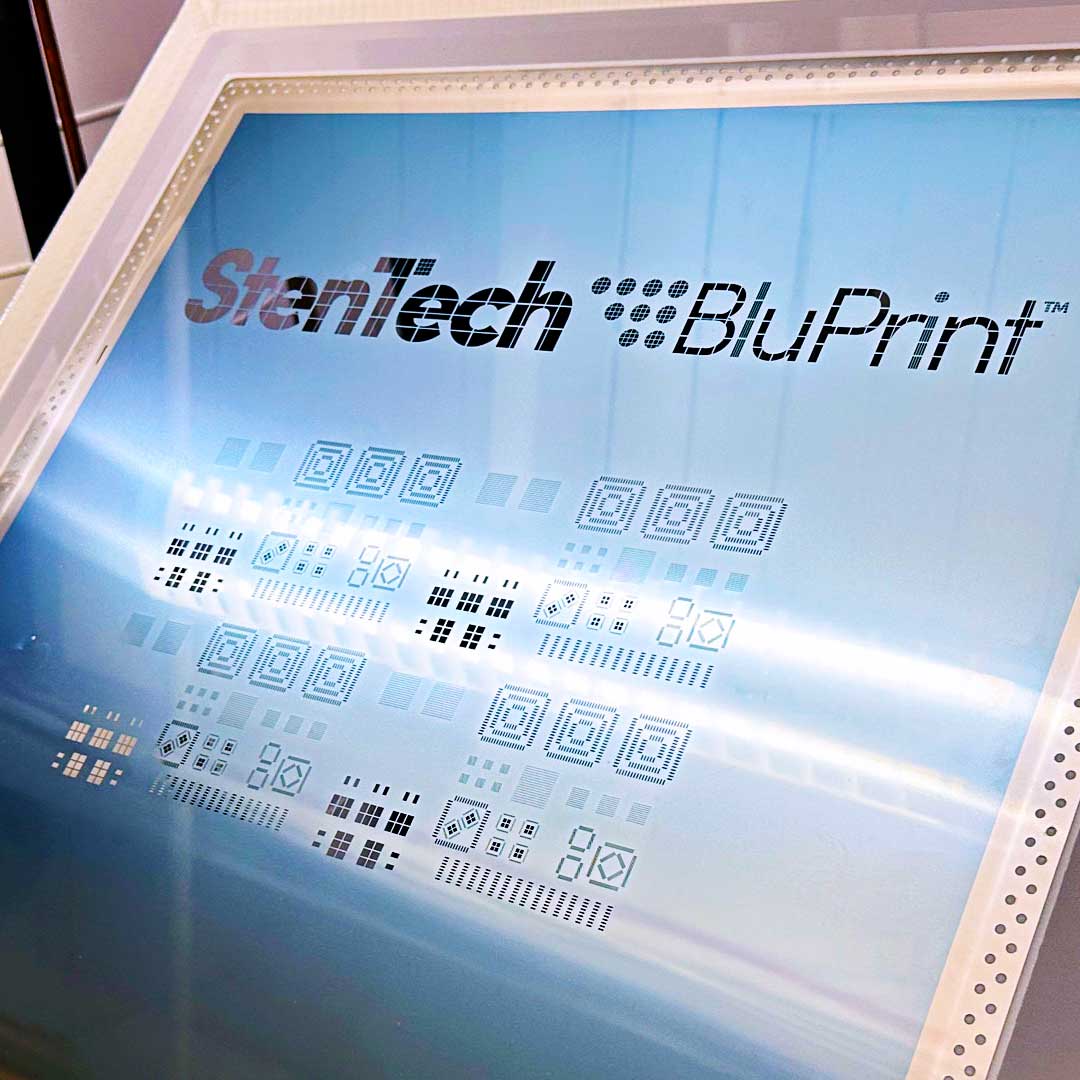

Revolutionary Precision Stencils

Redefining High-Volume Printing

Game-changing Throughput

while Reducing Operating Cost

StenTech BluPrint™ is highly durable vapor deposition coating designed to withstand the demands of any SMT line.

We understand the unique challenges faced in SMT production, including the gradual wear and tear stencils endure from frequent cleaning, squeegee pressure, and varying processes.

BluPrint™ improves transfer efficiency to 98%, ensuring consistent quality from the first print to the last, including high volume runs of 50,000 prints. This advanced coating technology enables engineers to push design boundaries, allowing for more intricate PCB designs and with lower area ratios than ever thought possible. This all while reducing the need for frequent stencil cleaning.

Contract manufacturers who have adopted StenTech BluPrint™ report reduced cleaning cycles by up to 300%. StenTech BluPrint™ optimizes the manufacturing process by reducing downtime, minimizing errors, and improving consistency. Whether you need to print 10 boards or 50,000,

BluPrint™ stencils maintain their performance, ensuring your operations are both reliable and cost-effective. With StenTech BluPrint™, you can achieve greater productivity, fewer disruptions, and more confidence in every print. This technology elevates your SMT processes to a new level of efficiency and reliability

Revolutionary Process. StenTech BluPrint™ PVD.

StenTech BluPrint™ PVD (Physical Vapor Deposited) Surface Treatment represents a groundbreaking technique for applying thin material films onto a substrate. This innovative process involves introducing chemical precursors into a reactor chamber, where they undergo chemical reactions and solidify as a deposited material on the substrate’s surface.

The continuous drive to reduce component sizes and circuit boards poses a challenge for solder paste printing with laser-cut stainless-steel stencils. Laser technology advancements align with coating finish improvements for these stencils. StenTech’s BluPrint™ PVD is meticulously designed to be the top choice in North America for meeting the evolving requirements of the semiconductor and EMS industry.

The absolute truest form of Nano coating at the particle level

In the StenTech BluPrint™ PVD process, the wafer is exposed to one or more volatile precursors, which react and/or decompose on the substrate surface to produce the desired deposit.

This process is called Ion Beam Deposition (IBD) and involves rotating “Targets” or “Precursors,” made from special materials, inside a chamber with stencils for coating. When heat and vacuum are applied, the materials undergo oxidation, vaporize, and then redeposit onto the stencil foil. These vapor-deposited materials form layers of color and coatings, resulting in a unique hydrophobic and oleophobic coating.

Engineered for High-Yield,

High-Volume SMT Production.

StenTech BluPrint™ PVD coating significantly enhances SMT stencil performance by improving durability and wear resistance, reducing the need for frequent replacements and maintenance in high-volume production environments. Its excellent thermal stability maintains stencil integrity during elevated-temperature soldering processes, while the physical inertness provides resistance to reactions with solder paste and other materials, ensuring long-term consistent performance.

Anti-stiction properties minimize solder paste adhesion, preventing defects such as solder bridging, and the smooth surface finish reduces friction to facilitate better paste release and higher-quality printed solder joints. The coating’s customizable properties, including thickness, hardness, and composition, allow manufacturers to tailor performance to specific applications, and the uniformity and robustness of the coating ensure consistent print quality over multiple production cycles, supporting high yields and reliable SMT assembly.

The world’s most sophisticated stencil surface treatment available.

StenTech BluPrint™ eliminates the need for frequent replacements and ensures a longer lifespan for the stencil, ultimately reducing maintenance and replacement costs associated with traditional coatings while dramatically enhancing overall performance.

01 UNIFORM COATING THICKNESS

StenTech BluPrint™ PVD ensures a uniform and conformal 1 atom thick coating, providing consistent thickness across complex geometries of SMT stencils. This uniformity is crucial for achieving precise and reliable solder paste deposition during the printing process.

02ENHANCED DURABILITY

StenTech BluPrint™ PVD coating can significantly improve the durability and wear resistance of SMT stencils. This is important in high-volume production environments where stencils are subjected to repeated use, reducing the need for frequent replacements and maintenance.

03HIGH THERMAL STABILITY

StenTech BluPrint™ PVD coating often exhibit excellent thermal stability, making them suitable for applications involving elevated temperatures during the soldering process. This stability helps maintain stencil integrity and performance under demanding manufacturing conditions.

04CHEMICAL INERTNESS

The chemical inertness of StenTech BluPrint™ PVD coating makes them resistant to reactions with solder paste and other process chemicals. This resistance contributes to the longevity of the stencil and ensures consistent performance over time.

05ANTI-STICTION PROPERTIES

StenTech BluPrint™ PVD coating can provide anti-stiction properties, reducing the likelihood of solder paste sticking to the stencil. This is particularly important for preventing defects such as solder bridging, ensuring clean and accurate paste transfer onto PCBs.

06SMOOTH SURFACE FINISH

StenTech BluPrint™ PVD coating typically results in a smooth surface finish on the stencil. A smooth surface minimizes friction during the printing process, facilitating better release of solder paste and improving the overall quality of printed solder joints.

07CUSTOMIZABLE PROPERTIES

StenTech BluPrint™ PVD processes allow for the customization of coating properties such as thickness, hardness, and composition. This flexibility enables manufacturers to tailor the coating to specific requirements, optimizing stencil performance for diverse applications.

08CONSISTENT PRINT QUALITY

StenTech BluPrint™ The combination of uniform coating thickness, durability, and other properties ensures consistent print quality over multiple production cycles. This is essential for achieving high-yield and reliable SMT assembly.

Engineered for High-Yield,

High-Volume SMT Production

BluPrint™ PVD has been recognized with multiple industry awards, including the 2024 CIRCUITS ASSEMBLY NPI Award and the 2024 Global Technology Award. If you’re ready to experience the difference firsthand, we offer a special first test stencil at a reduced rate — request a virtual demo today and see the performance for yourself.

Request a virtual demo