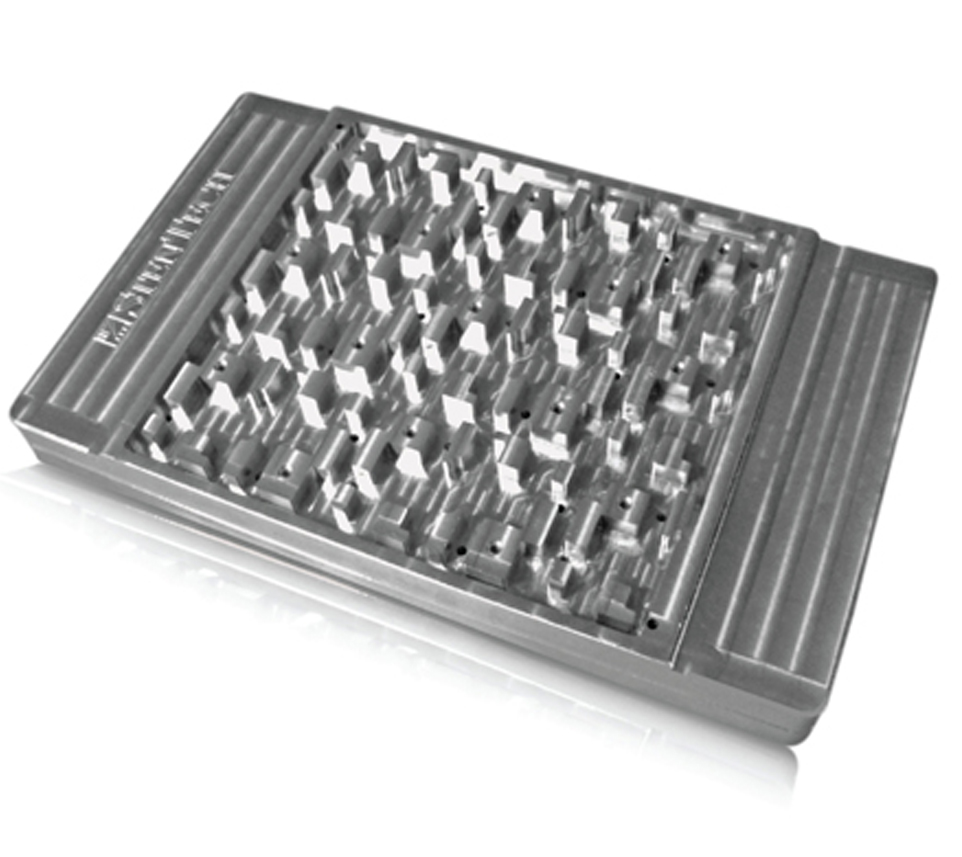

- Vacuum plates will ensure proper support for double-sided boards

- Quick and easy setup

- Consistent board support ensures consistency in paste deposits, reducing reworks and saving money

- Dedicated tooling is the industry standard for ensuring fast and repeatable setup and maintaining process stability

- Dedicated screen-print tooling is a proven way to reduce variation and defects

- Helps to ensure fast and repeatable setup, while maintaining process stability

Varying placement of magnetic pins from setup to setup can cause defects that are difficult to troubleshoot. Even under normal squeegee pressure, a board can flex and move if the Z plane of the board is not flat and stable. When a board flexes, the X-Y alignment, snap-off and squeegee pressure are no longer constant.

The screen-print process is full of variables that affect the success of the SMT process as a whole. Dedicated screen-print tooling is a proven way to reduce variation and defects.