- SAME DAY DELIVERY of your stencils*

- Higher volume of paste release

- More uniform shape on solder deposits

- Higher transfer efficiency and print yields

- Greater yields on low-area-ratio / miniaturized applications

- Reduced underside wiping

- Reduced surface energy of paste contact area

- Better contour definition and lower failure

Permanent hydrophobic coating for

improved paste transfer, higher yields,

and precise SMT printing.

Next-Level SMT Printing with Advanced Nano Technology.

StenTech’s award-winning Advanced Nano is a highly unique coating that transforms SMT stencil performance. Unlike traditional stencils, this coating is applied exclusively to the bottom side of the stencil and inside the apertures, leaving the squeegee side uncoated. Utilizing a specialized 1–2 μm hardened polymer layer that is sprayed in a controlled chamber and heat treated, Advanced Nano provides a permanent hydrophobic surface that repels solder flux.

This innovative anti-adhesion property improves paste transfer efficiency, producing higher volumes of paste release, more uniform solder deposits, and better contour definition. It enhances yields on low-area-ratio and miniaturized applications while reducing underside wiping and the surface energy of paste contact areas.

The result is consistent, high-quality printing with fewer defects and improved precision, helping manufacturers achieve greater efficiency and reliability in electronic assembly. With the added benefit of same-day stencil availability, Advanced Nano enables rapid integration into production lines for immediate performance improvements.

* Same-day turnaround is available when final files are submitted early and approved. Please note that deadlines may vary by facility.

Features & Benefits

Durablility

A|N achieves a 9h hardness within 1 hour of curing the stencil. Coated stencils should receive special care to avoid unnecessary wear.

Same Day Delivery

A|N is the only permanent coating that is available to customers next day if the order is received within a manageable timeframe. Please contact your StenTech facility for availability and scheduling.

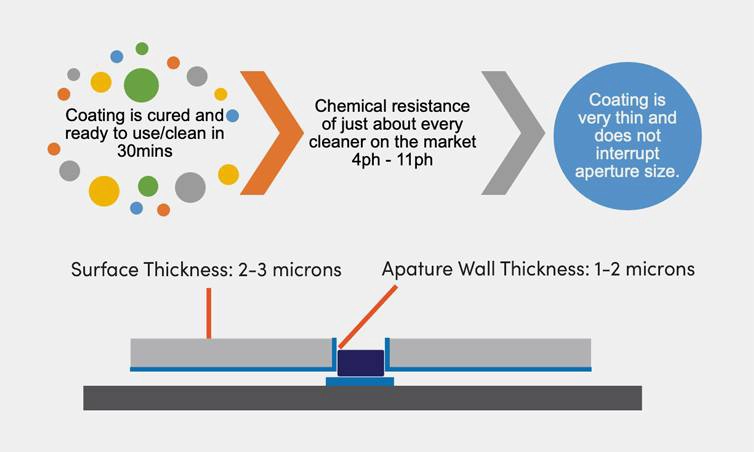

Chemical resitant

A|N holds up to almost all stencil cleaners, both acidic and alkaline. That said, it is recommended to stay within a ph range of 4-11.

Coating thickness

The coating thickness is around 2µm on the surface and around half of that thickness on the aperture walls.

Better contours

With the aperture walls being coated, A|N users will notice much stronger brick formations, as well as more paste volume.

Underside cleaning

Due to the anti-adhesion or "non-stick" characteristics, underside cleaning is dramatically reduced achieving a better yield

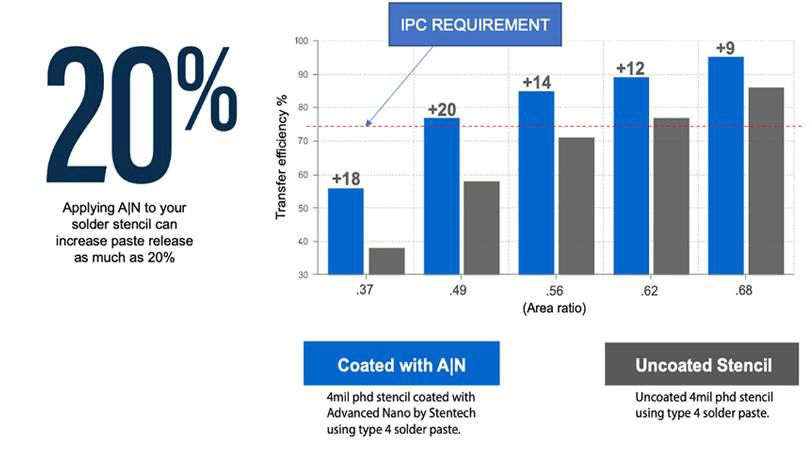

Transfer efficiency

Testing demonstrates transfer efficiency gains of up to 20%. See below.

Less bridging

You will see significantly less bridging due to the paste efficiency benefits achieved with A|N coating.

Uniform coating

Advanced Nano provides a uniform coating across the stencil, with thickness variance held to just ±1 µm.

Upgrade Your Process: Fast, Reliable, Efficient Stencil Coating

StenTech Advanced Nano coating delivers the performance and reliability you need to keep production running at its best. By reducing downtime, rework, and production risks, it helps you achieve higher yields with less maintenance. The longer stencil life saves you money, while improved efficiency and consistency boost your ROI.

Recognized with the NPI Award 2023, Global Tech Award 2023, and Mexico Tech Award 2023, Advanced Nano is the trusted choice for manufacturers who want to work smarter, faster, and more cost-effectively.

Although StenTech provides a variety of advanced stencil coatings, Advanced Nano continues to be the top choice for many customers who depend on its proven performance and have integrated it into their production processes.