Component & Dispensing Solutions.

At StenTech, we design and manufacture a complete range of specialized fixtures that ensure components are accurately positioned, precisely aligned, and fully protected throughout every stage of the assembly process. Our solutions are engineered to meet the exact requirements of each customer’s product and process, whether for high-volume manufacturing, high-mix/low-run production, or highly specialized builds.

From advanced placement tools that guarantee first-pass accuracy to protective wash baskets that safeguard PCBs during cleaning, our fixtures are built to optimize process flow, maintain dimensional integrity, and reduce costly rework. We offer component alignment canopies to keep parts secure during soldering, custom press fit fixtures to prevent damage during high-force connector insertion, and tailored matrix trays to organize and present components for efficient handling.

Our expertise also extends to dispensing and potting pallets that ensure precise material application, conformal coating fixtures that protect sensitive areas while speeding production, and edge stiffeners that prevent board sag during processing. Every solution is designed for durability, repeatability, and seamless integration into your workflow, helping you achieve consistent quality and efficiency across a wide range of manufacturing applications.

Component Positioning, Alignment & Hold-Down Canopies

Precise component placement is essential to product performance, especially for assemblies that must align with other devices or parts later in the manufacturing process. StenTech designs fixtures that ensure components are positioned and aligned to exact designer specifications, reducing the risk of misalignment and costly rework.

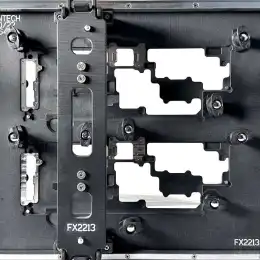

Our specialized hold-down canopies address one of the most common causes of rework — unseated components on complex assemblies. Engineered for durability and ease of use, these canopies mechanically secure light or unstable components during soldering, maintaining alignment throughout the process.

Available in a wide range of designs and custom configurations, our solutions combine accurate positioning with mechanical stability to deliver consistent, high-quality results every time.

Press Fit Fixtures

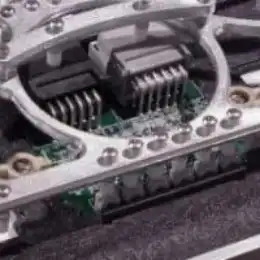

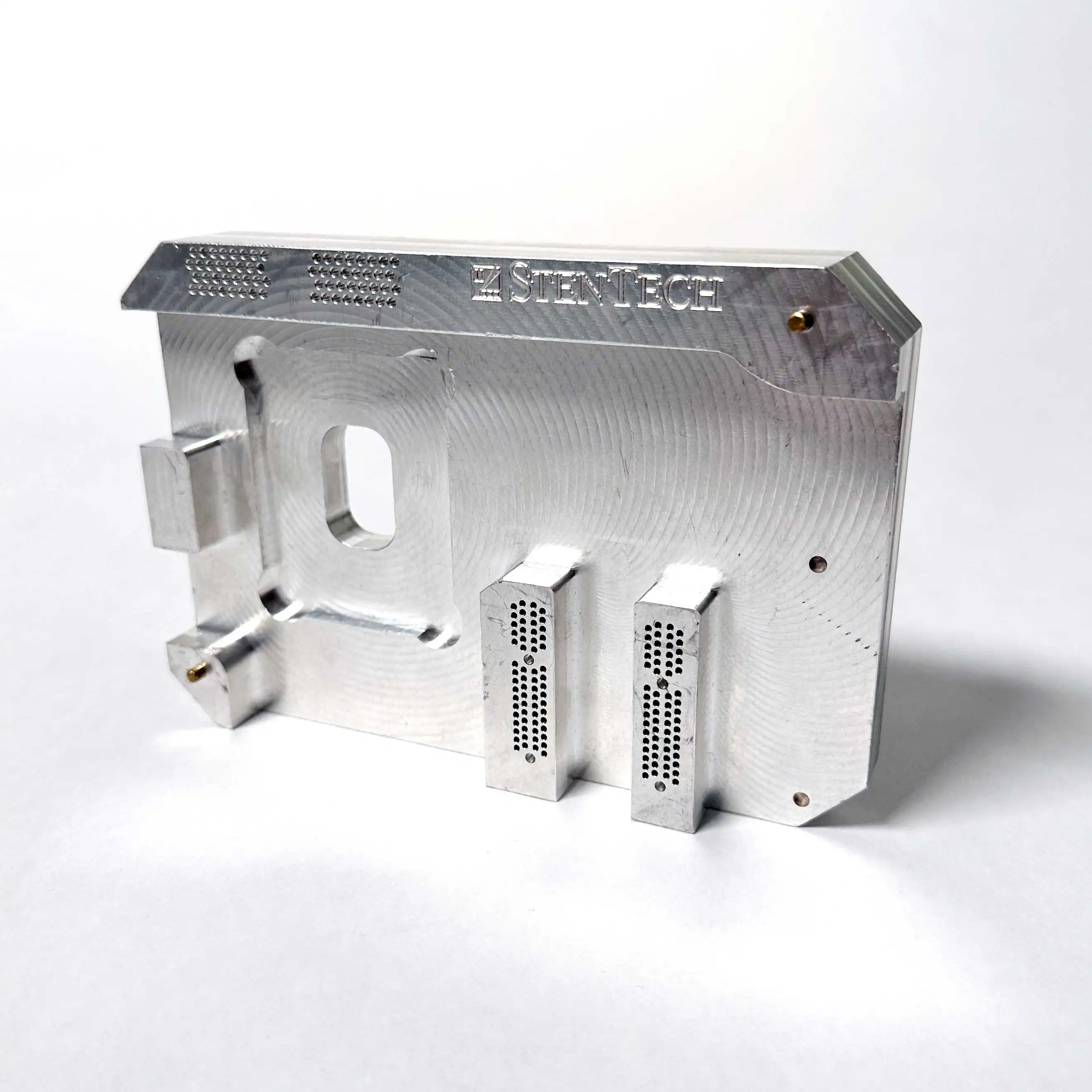

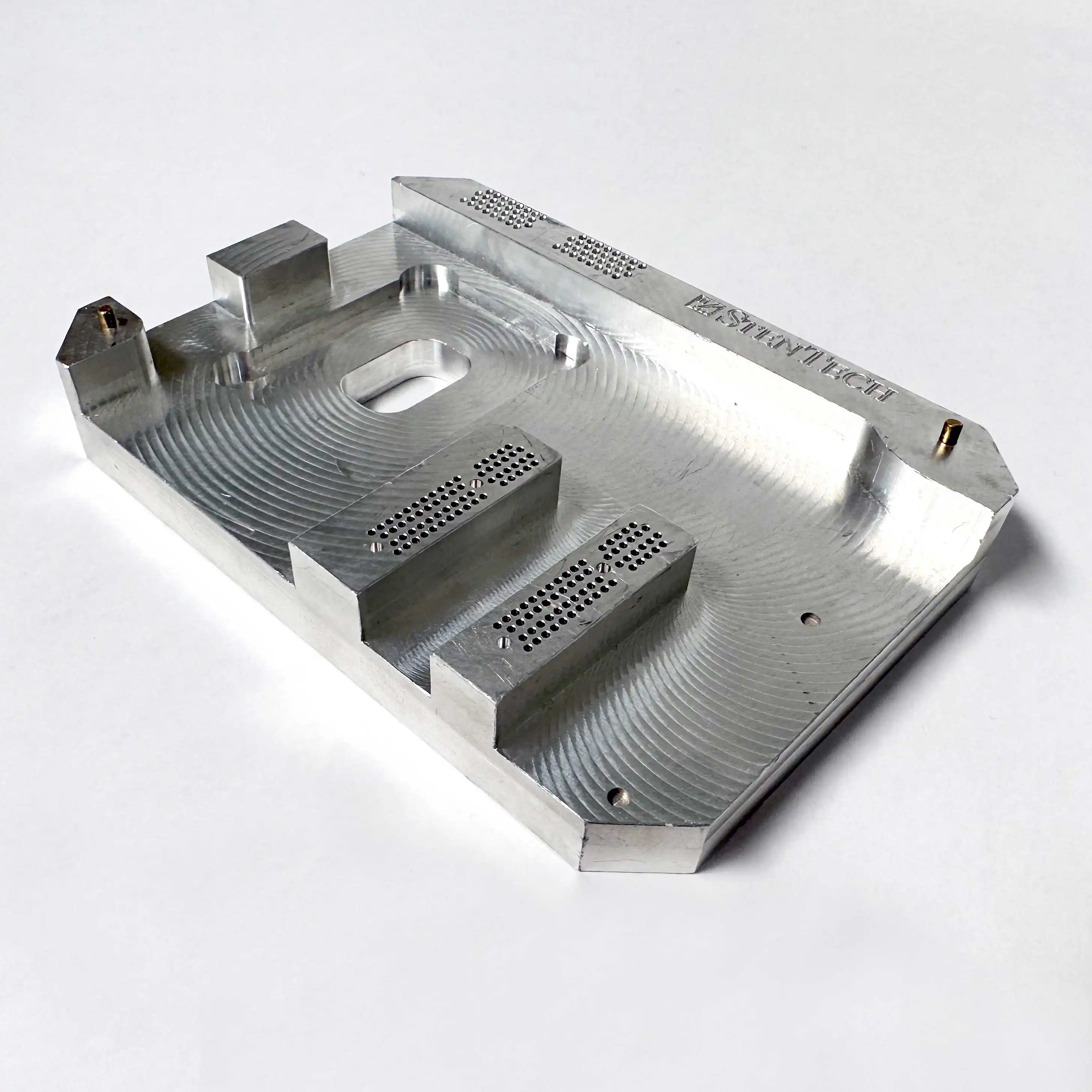

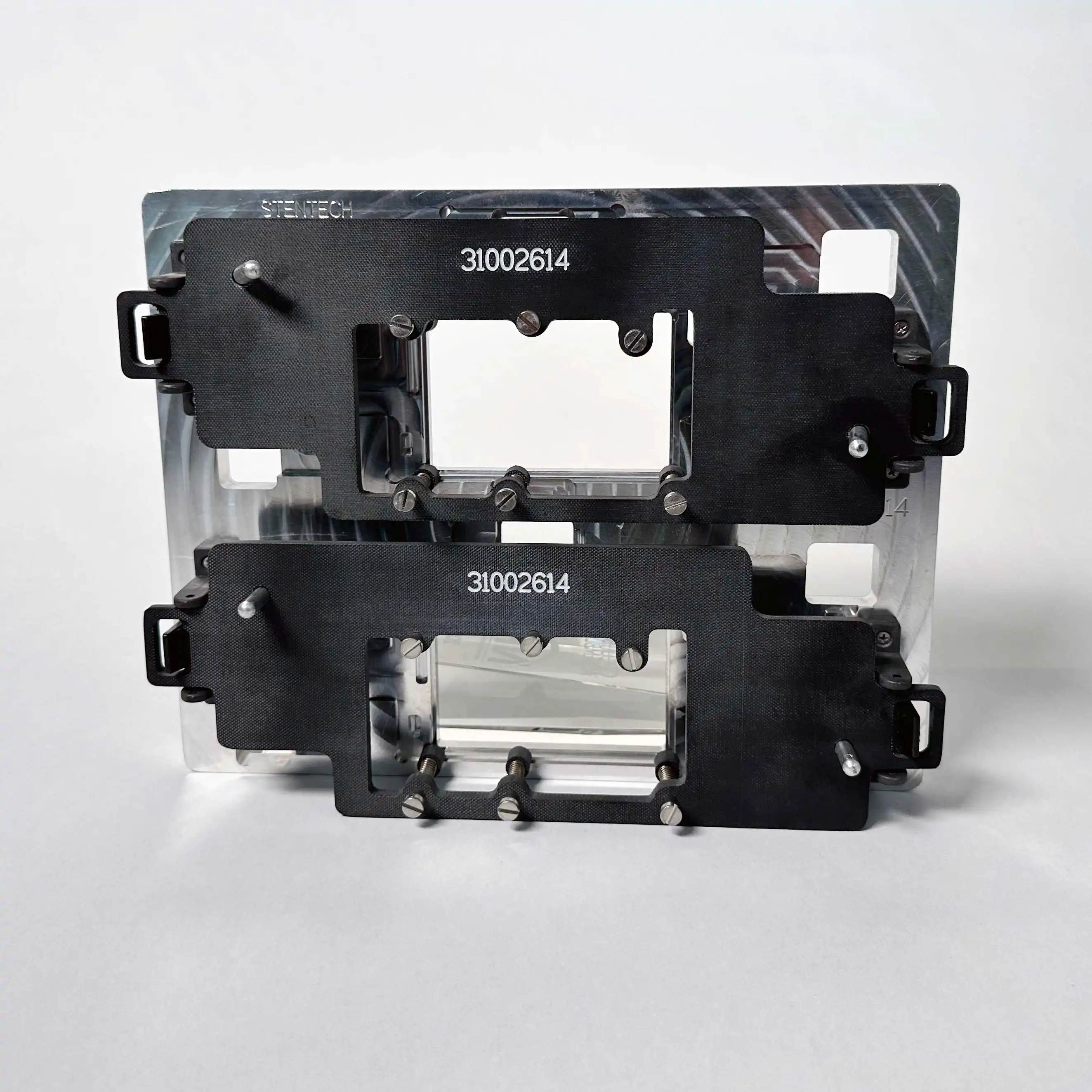

StenTech press fit fixtures provide complete, stable support for PCBs during high-force connector insertion, preventing board flex, misalignment, and potential component damage. Each fixture is engineered to match the board layout, connector specifications, and production requirements, ensuring optimal fit and performance.

Constructed from materials such as ESD-safe composite, G10, aluminum 6061, or stainless steel, these fixtures combine durability with protection against electrostatic discharge. Their precision design reduces setup time, minimizes rework, and can be configured as universal tooling for multiple board designs, making them ideal for both dedicated high-volume runs and high-mix manufacturing environments.

By delivering accuracy, repeatability, and adaptability, StenTech press fit fixtures help manufacturers maintain quality, protect assemblies, and streamline production.

Matrix Trays & PCB Wash Solutions

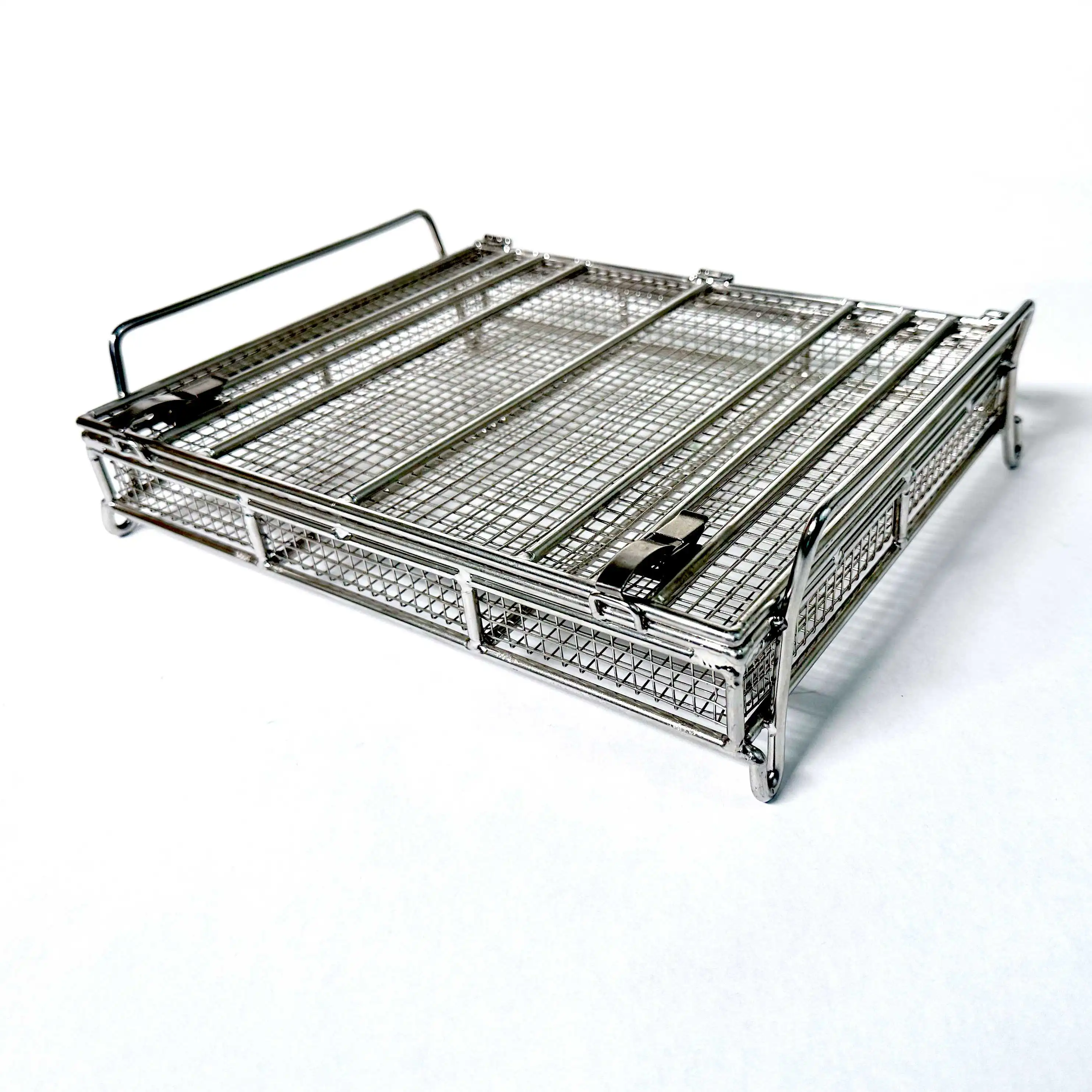

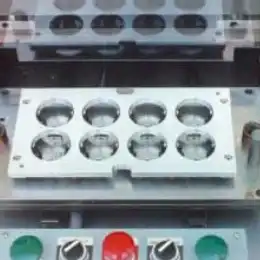

StenTech’s matrix trays and wash fixtures are designed to protect, organize, and streamline handling of components and assemblies throughout the manufacturing process. Matrix trays precisely nest multiple arrays of components, keeping them secure, accessible, and organized to improve workflow and reduce handling time. Each tray can be customized for component size, shape, and storage requirements.

For cleaning processes, our wash baskets and trays safeguard PCBs during high-pressure wash cycles, preventing movement and damage. Heavy-duty stainless steel wash trays are built from 16 ga. perforated material, fully welded and corner-braced for strength, with a retractable fine-mesh drape lid to minimize PCA movement. ESD-safe wash mats, CNC-cut from textured, grippy rubber, protect delicate components from tray contact during cleaning. For high-reliability or fragile assemblies, we also provide dedicated or adjustable pallets to suspend boards above or below conveyor contact, ensuring the highest level of protection during the wash process.

Dispensing & Potting Fixtures

StenTech designs precision fixtures that securely nest and position components for a variety of applications, including adhesive dispensing, underfill, dielectric potting, and more. Each fixture is engineered to maintain exact alignment and stability throughout the process, ensuring that materials are applied with accuracy and consistency. By controlling part positioning, these fixtures help prevent material waste, reduce operator handling, and minimize the risk of damage to sensitive components during processing.

Our designs also enhance overall assembly efficiency by addressing specific production challenges. Fixtures can be tailored to manage wire harnesses neatly, hold odd-shaped assemblies securely, or protect delicate displays from accidental contact or overspray. Whether for small-batch prototyping or high-volume manufacturing, StenTech’s dispensing and potting solutions are built for repeatability, durability, and seamless integration into your workflow, delivering cleaner results, faster cycle times, and greater process control.

Conformal Masking Fixtures

StenTech conformal coating pallets are engineered to provide precise clearance for overhanging components, molded housings, and irregular board shapes, while masking areas that should remain free of coating. Each fixture is custom-designed to match the exact dimensions and layout of the board, ensuring that coating is applied only where required. By directing overspray away from sensitive areas and toward the machine’s filter system, our pallets help maintain product quality and protect high-value components.

Constructed from solvent-resistant materials, these fixtures can be cleaned quickly with a dip process, reducing maintenance effort and keeping them production-ready. By reducing or eliminating the need for manual masking, conformal coating pallets cut downtime, lower labor costs, and deliver more consistent, repeatable coating coverage. For high-mix, low-volume environments, we also offer adjustable versions that allow a single fixture to accommodate multiple board types, making them a flexible, cost-effective solution for complex manufacturing operations.

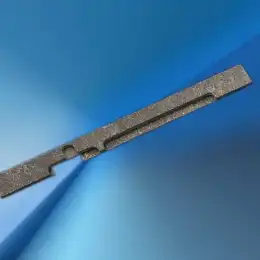

Edge Stiffeners & Bench Top Assembly Fixtures

StenTech provides practical solutions for maintaining PCB integrity and streamlining manual assembly processes. For large or heavy assemblies prone to sagging during processing, our custom snap-on edge stiffeners maintain board rigidity, prevent distortion, and protect components located near the board edge. Each stiffener is built to match specific board thicknesses, ensuring a secure fit without interfering with surrounding components.

Our bench top assembly fixtures free up skilled operators by holding components and assemblies securely during hands-on tasks. We design custom solutions for specialized processes such as thermal transfer tooling, lock tab forming, flex circuit wrapping, and screw guides, ideal for applications where standard tooling isn’t sufficient. By combining stability with tailored functionality, these solutions improve operator efficiency, enhance process accuracy, and protect assemblies throughout production.