Coatings and Polishes

At StenTech Parts, we know that the right finish can make all the difference. Our advanced coating and polishing processes not only improve durability and corrosion resistance but also enhance conductivity, appearance, and overall performance. From protective coatings that deliver long-lasting wear resistance to chemical polishing that creates smooth, flawless surfaces, every finish is designed to ensure your parts meet the most exacting standards.

We offer a wide range of finishes, including electro polishing, anodization, bright tin, black zinc, matte tin, gold, passivation, bright nickel, nickel sulfamate, and more, giving you the flexibility to match each part’s requirements with the right protective and performance-enhancing solution. With our expertise, your parts don’t just perform, they last longer, look better, and work harder in the most demanding applications.

Our Coatings & Polishes Line-up

- Electro Polishing

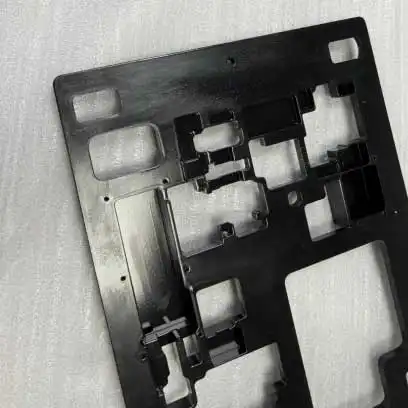

- Anodization

- Bright Tin

- Black Zinc

- Physical Vapor Deposition - Coming Soon

- Matte Tin

- Gold

- Passivate

- Bright Nickel

- Nickel Sulfamate ...& more

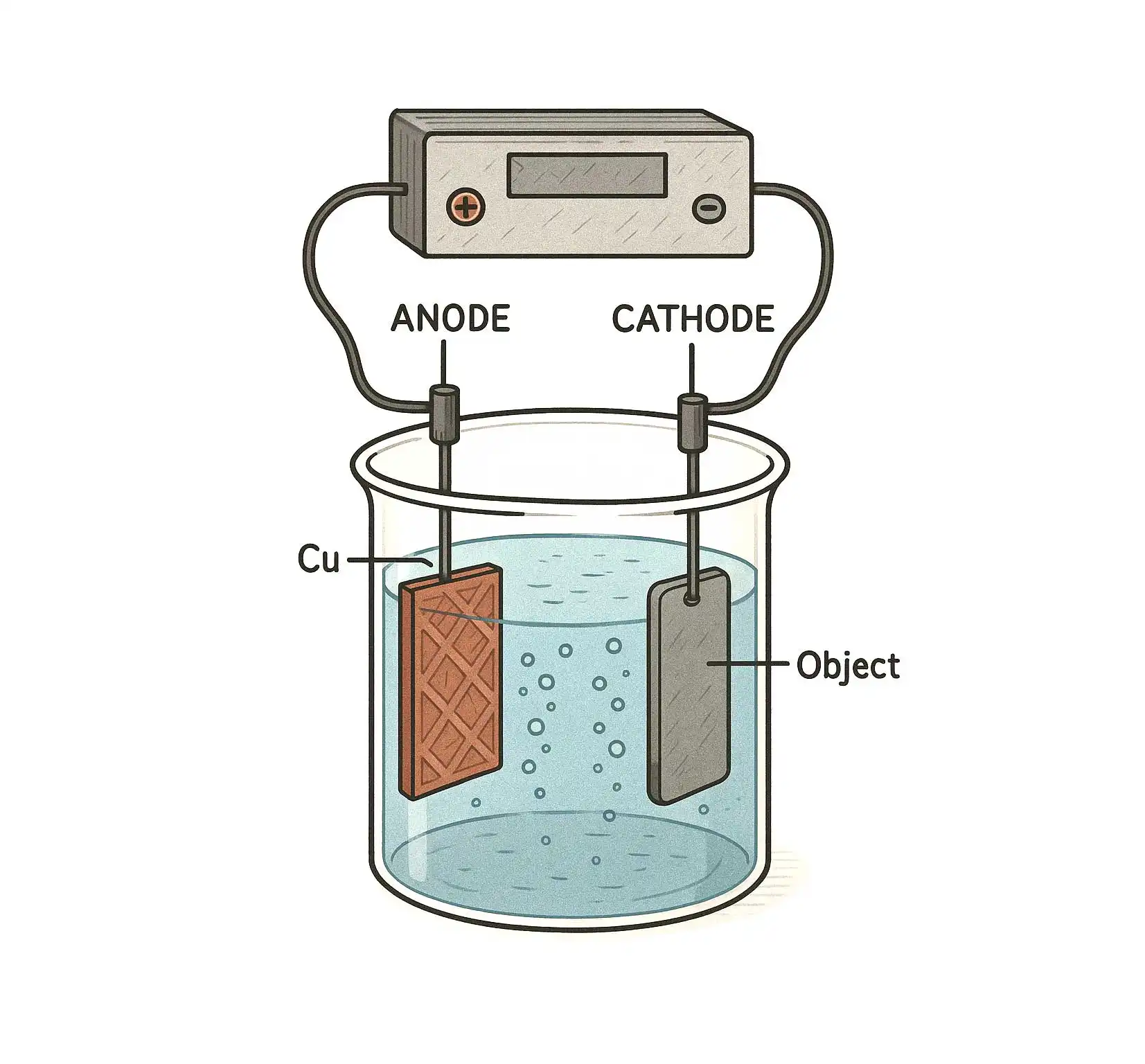

Electro Polishing: A Smooth Finish With Lasting Benefits

Electro polishing is an electrochemical process that removes a thin layer of material from the surface of a metal part, leaving it exceptionally smooth, clean, and corrosion-resistant. By using an electric current in a chemical bath, microscopic peaks on the metal surface are dissolved, reducing roughness and creating a bright, reflective finish.

The process not only enhances appearance but also improves performance by reducing friction, eliminating burrs, and preventing contaminants from adhering to the surface. At StenTech Parts, electro polishing is one of the many finishing options we offer to ensure your components meet the highest standards of quality, reliability, and durability.

Anodization: Strength, Protection, and Appearance

Anodization is an electrochemical process that transforms the surface of aluminum and other metals into a durable, corrosion-resistant oxide layer. This controlled oxidation not only strengthens the surface but also enhances wear resistance and provides an ideal base for dyes or additional coatings. The result is a finish that improves both performance and appearance while maintaining the metal’s natural properties.

At StenTech Parts, anodization is one of the key finishing processes we offer, delivering components that are tougher, longer-lasting, and tailored to the specific needs of your application.

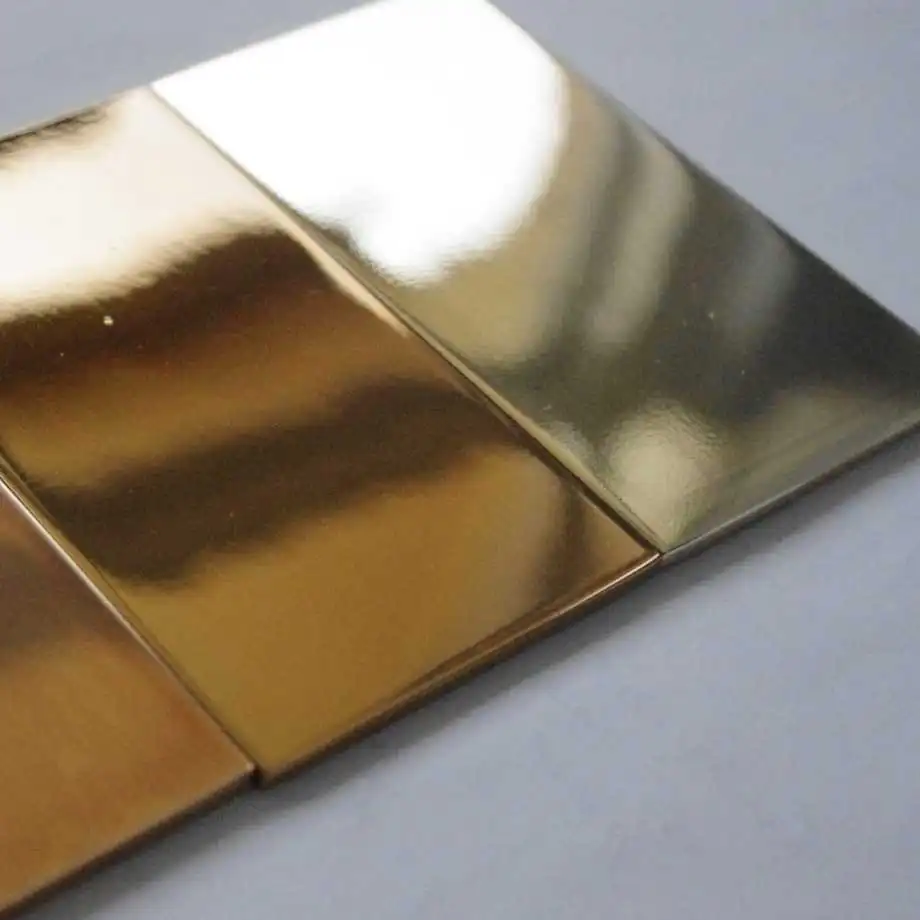

Gold Plating: Superior Conductivity and Corrosion Resistance

Gold plating is the process of depositing a thin layer of gold onto the surface of a metal part to enhance conductivity, prevent oxidation, and improve overall durability. Known for its excellent resistance to tarnish and corrosion, gold plating is widely used in applications where reliability and signal integrity are critical, such as electronics, medical devices, and aerospace components.

Although more expensive than many other finishes, gold plating delivers unmatched benefits where performance cannot be compromised. At StenTech Parts, we provide gold plating as part of our comprehensive finishing options, ensuring your parts not only perform at the highest level but also maintain long-term stability in demanding environments.

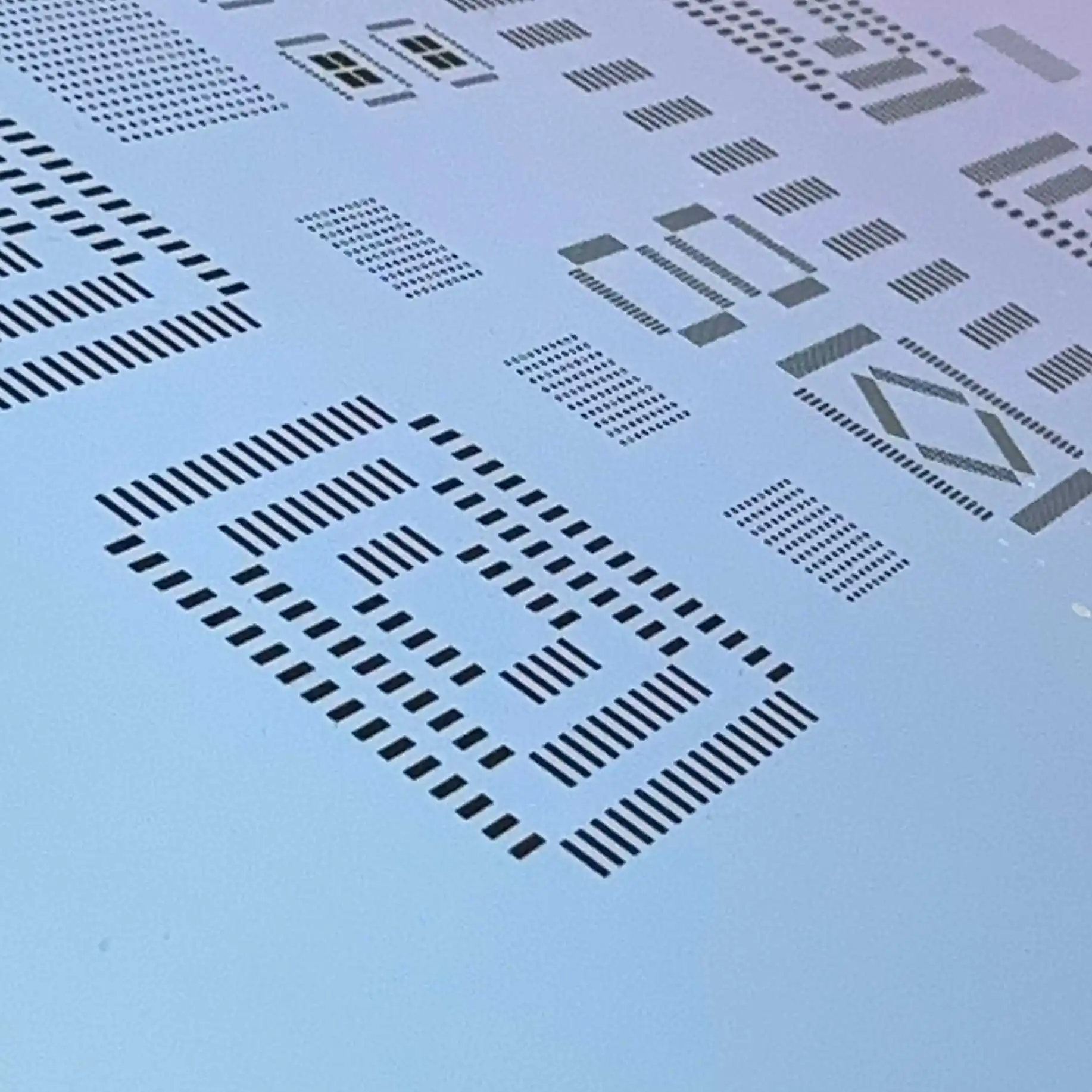

Physical Vapor Deposition (PVD): Advanced Coating Technology

Coming soon to StenTech Parts, Physical Vapor Deposition (PVD) is a cutting-edge process that deposits thin, durable coatings onto metal surfaces in a vacuum environment. These coatings enhance wear resistance, reduce friction, and improve overall performance without altering the part’s core properties.

StenTech already holds the exclusive process for SMT stencil coating, setting the industry standard with our BluPrint™ PVD technology. Now, we are developing specialized PVD coatings for parts, bringing the same breakthrough durability, consistency, and performance benefits to precision components across industries. This innovation will allow us to deliver parts that not only meet your specifications but also last longer and perform better in demanding environments.

Bright Nickel: Durable Protection with a Polished Look

Bright nickel plating is a versatile finish that combines durability, corrosion resistance, and a smooth, reflective appearance. The process deposits a uniform layer of nickel onto the surface of a part, creating a hard, protective barrier that enhances wear resistance while also delivering a bright, decorative finish.

At StenTech Parts, bright nickel is a trusted option for customers who need both performance and appearance, ideal for applications where strength, conductivity, and an attractive finish are equally important.