Materials & Processes

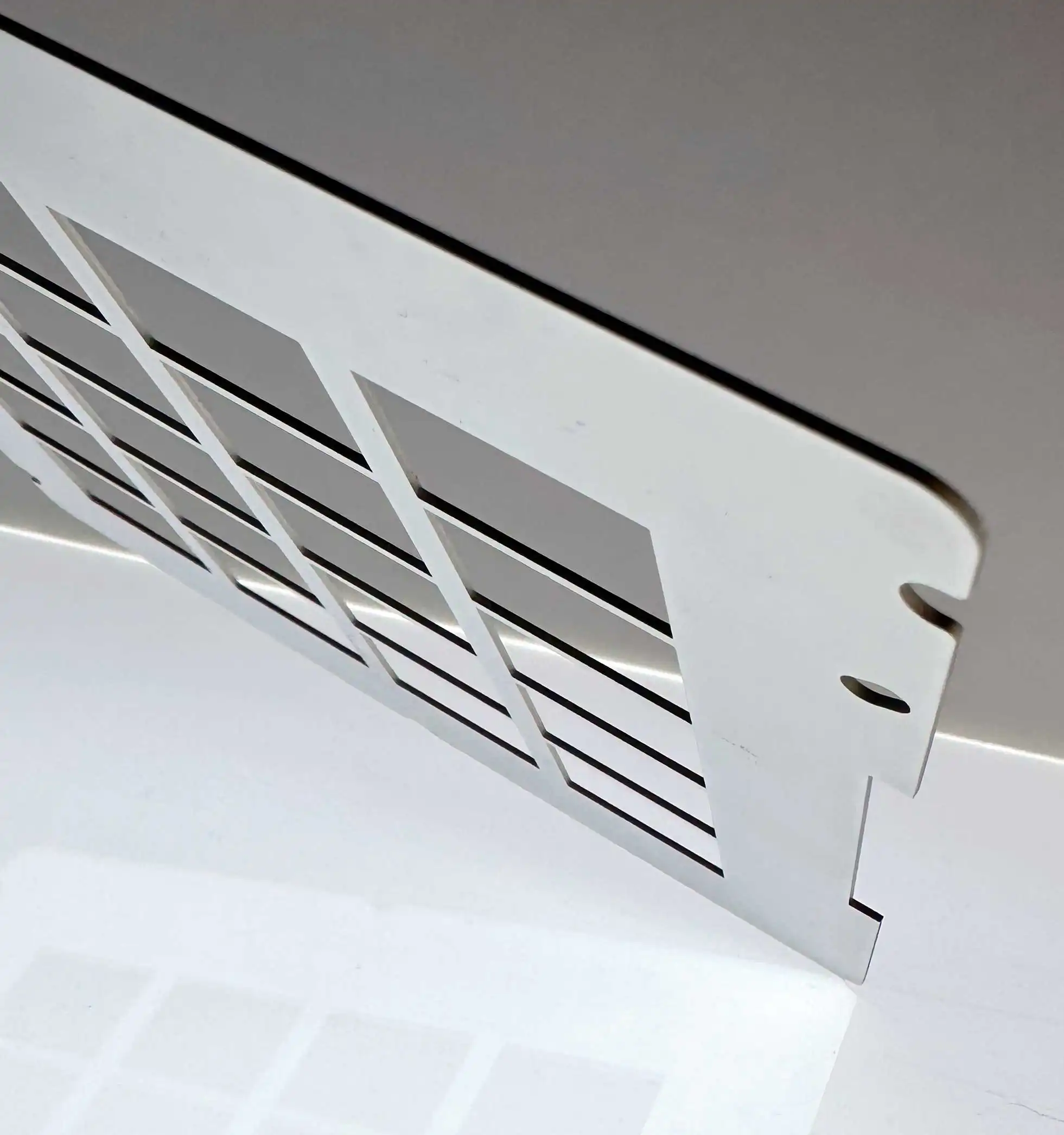

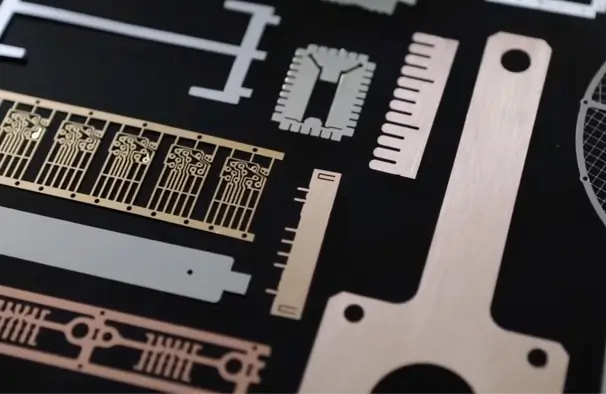

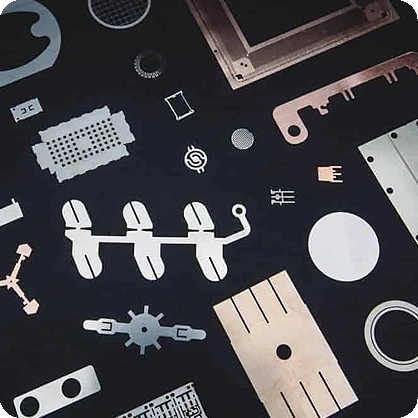

For over 25 years, StenTech Parts has manufactured thin metal components from .002" to .250" using advanced processes such as chemical etching and laser cutting. From rapid prototypes to large-scale production, our network of facilities has the capacity and precision to deliver exactly what you need.

One of the advantages of photo etching metal is that the chemical etching process is suitable for many different types such as stainless steel, cold-rolled steel, aluminum, nickel/silver, brass, copper, phosphorus bronze, beryllium copper as well as some exotic metals including Molybedum and Inconel.

We stock a wide range of metals suitable for the most commonly requested parts in a variety of industries. For example, most electronic components require a non-corrosive, highly conductive metal such as copper and phosphorus bronze. In the automotive and aerospace industries, for some applications the weight and strength of the metal are important considerations; therefore, aluminum is a popular choice. And medical device parts benefit from the non-corrosive property of stainless steel.

Some metals require variations in the etching process, for example, etching copper uses a different etchant than steel, and the temperature in the etcher must be lower to etch aluminum. Also, depending on the part features and metal thickness, the time it takes to etch will differ. Nevertheless, all metals are etched to precision.

Our Material Line-up & Processes

WHITE METALS

- Stainless Steel

- Cold Rolled Steel

- alloy 42

- Nickel Silver

- Nickel

- Kovar

- Aluminum

- Inconel

- Molybdenum

- Hy-Mu 80

- Invar

RED METALS

- Copper

- Beryllium Copper

- Brass

- Phosphorus Bronze

NON-METAL

- Silicon

- Plastic

PROCESSES

- Laser Cutting

- Electroform

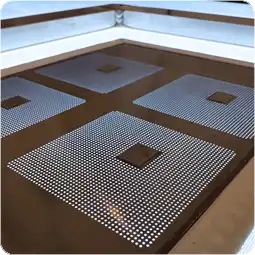

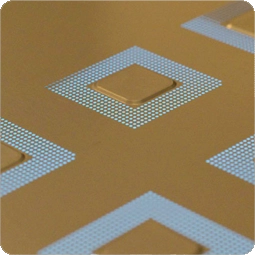

- Chemical Etching

- Machining

- Punching

- Casting

- Forging

- Welding

- Bending and Forming

Materials – From Ultra-Thin to Heavy-Duty

Our metal stock reflects the most requested materials for photo etched parts, including various tempers and thicknesses. This is not a complete list, so if you do not see a metal that you require please contact us for more information. Our metal supply partners have an excellent delivery response rate.

If we do not have a certain metal thickness in stock, we can "mill down" or etch the metal to the desired thickness. This is one of the benefits of choosing the chemical etching process. The etching process will not alter the metal properties or flatness of the metal, and you will not have to wait until the metal is in stock, which means lower lead times.

The largest sheet of metal we can etch is 24" x30". However, a one-inch border around the perimeter is necessary to maintain part tolerances, so the largest part we can actually etch is 23" x 29".

Stainless Steel – Available in numerous alloys, including 303, 304, 17-7, and 15-5, stainless steel offers exceptional strength, durability, and corrosion resistance. Ideal for industries from aerospace to medical, it often undergoes finishing processes such as passivation or polishing for enhanced performance.

Aluminum – ightweight, highly machinable, and available in grades like 6061, 7075, and MIC-6. Aluminum is used in aerospace, electronics, and industrial applications for its ductility, corrosion resistance, and thermal conductivity. It is often anodized for added protection and aesthetics.

Titanium – With a high strength-to-weight ratio and 40% lighter than steel, titanium is essential in aerospace, medical, and high-performance automotive parts. It withstands extreme environments while maintaining structural integrity.

Brass – Machined in grades such as C-260, C-360, and C-646, brass offers excellent machinability, corrosion resistance, and durability, making it ideal for bushings, bearings, gears, and fittings.

Copper – Used in applications requiring high electrical and thermal conductivity. Grades such as C10100, C11000, and C10200 are machined into busbars, heat exchangers, shielding components, and more.

Metal alternatives: Plastics – High-performance plastics like PEEK, HDPE, and polycarbonate are machined for industries such as medical, semiconductor, and food processing, offering lightweight, corrosion-resistant alternatives to metals.

What are the benefits of photo etching metal?

Photo etching is a great alternative to other metal fabrication methods such as stamping, laser cutting, wire EDM, and water jet cutting. Unlike these other processes, metal etch can achieve all the following results without compromising the part's function and quality.

01 Unaltered metal properties

no machining heat-affected zones

02 Burr and stress-free

no need for secondary deburring operations

03 Low tolerances

on part dimensions without compromising part design

04 No pitts

Smooth even surfaces