Precision CNC Machining Services

At StenTech, our CNC machining delivers high-accuracy parts for the most demanding industries, where failure is not an option. We combine advanced technology, engineering expertise, and rigorous quality control to produce components that meet the tightest specifications and perform flawlessly in critical applications.

Using state-of-the-art computer-controlled equipment, we translate digital designs into precision parts with exceptional repeatability. Every detail is programmed into our systems, eliminating the inconsistencies of manual machining and ensuring each component matches its intended design exactly.

While standard CNC machining offers impressive accuracy, our precision CNC machining goes further. By holding tolerances to microns, we can produce complex geometries and intricate features that meet the strictest industry requirements. This capability is vital for sectors such as medical, aerospace, defense, and electronics, where even the smallest deviation can compromise performance, safety, or compliance.

From single prototypes to high-volume production runs, our approach ensures dimensional accuracy, surface quality, and consistency across every part we produce—giving our customers the freedom to design without compromise.

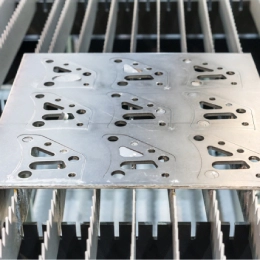

Machining Capabilities

In addition to our well-known tooling expertise, StenTech Machining offers a full range of CNC capabilities to handle projects of any complexity. Our multi-axis CNC machines can produce intricate geometries, tight-tolerance features, and precision finishes in a single setup, reducing lead times and improving accuracy.

We work with a wide variety of materials, including aluminum, stainless steel, titanium, specialty alloys, engineering plastics, and advanced composites. Whether you need a one-off prototype, a short production run, or high-volume manufacturing, we deliver fast turnaround without compromising quality.

Our experienced engineering team collaborates closely with customers from the design stage through final inspection, recommending the most efficient machining strategies, tooling approaches, and material choices to optimize performance, durability, and cost-effectiveness. Every project benefits from our commitment to precision, consistency, and on-time delivery.

Our Material Capabilities

Visit PageCNC Machining Tolerance

Precision starts with understanding and controlling tolerances. Typical CNC machining tolerances are ±0.005 inches (0.127 mm), with high-precision machining reaching tolerances as tight as ±0.0005 inches (0.0127 mm). The achievable precision depends on the type of machine, the hardness and machinability of the material, and the complexity of the part.

Tolerances are vital for ensuring uniformity so that parts fit and function correctly, for maintaining reliability and extending product life cycles, and for protecting quality reputations in industries where performance and safety are non-negotiable. Certifications such as ISO 9001:2015 and AS9100 depend on the ability to meet these stringent requirements.

Examples of CNC precision machining parts tolerances are:

- CNC technology: CNC machining, CNC lathes,

CNC Mills, and others can hold a tolerance of +/- 0.0254mm to +/- 0.0508mm. - CNC Micro Machining EDM: Can hold as tight as +/- 0.010mm to +/- 0.025mm.

- CNC Fiber Laser machining: Holds a tight tolerance of +/- 0.0127mm to +/- 0.0254mm.

- CNC Laser: UV Laser Machining: As tight as +/- 0.0127mm to +/- 0.0254mm.

- CNC Femto Laser Machining: Can be as tight as +/- 0.001mm to +/- 0.010mm.

Benefits to Having a Tolerance:

VIEWThere are levels of tolerance to all industries and what is acceptable for one, may not be to the another. They do share in the need for having a tolerance applied to the parts requirements. Without this control and standardization to a level of quality, lives would be in jeopardy. Some examples of the benefits of tolerances for CNC machining manufacturing:

- Uniformity: CNC precision parts manufactured under a tight tolerance can be replaced with confidence that the unit or device will continue to function properly.

- Sustained function: A CNC machined components tolerance allows for a longer life cycle of the machined part. Industries such as medical, food, aerospace, automotive, nuclear science all require tolerance for the proper function of the implemented manufactured parts and public safety.

- Business growth: Business goals are to create more business and opportunities. CNC machining parts manufacturers rely on their reputation by providing products that perform. Tolerance increases the quality of the product and integrity of the supplier.

- Industry Certification: CNC machining parts manufacturers go through certifications such as ISO 9001-2015 or ASTM 9100 for example. Many companies will only do business with services providers who are certified. Being certified and having the capabilities to hold the tolerances required is essential to public safety.

Tolerance is vital element to not only to CNC precision parts, but to all industries supporting manufacturing. Without this range of acceptable deviations, there would be no level of confidence in the products or services we use. The stringent demands of the airline industry the medical industry, and so on have demanded these safeguards be embedded in manufacturing to save lives and to keep our critical needs and goods at the highest levels possible.

High Precision Machining Explained:

VIEWHigh precision machining refers to a manufacturing process that utilizes computer numerical control (CNC) machines to create parts with exceptionally tight tolerances. These tolerances can be as close as ±0.0005 inches (0.0127 mm), which is roughly the thickness of a human hair.

This level of accuracy ensures that the parts fit perfectly in their designated assemblies and function flawlessly in demanding applications. Precision CNC machining parts are essential in industries such as aerospace, medical devices, and automotive, where even the slightest deviation can lead to significant performance issues.

Beyond tight tolerances, high precision machining often involves:

- Advanced CNC machines: Sophisticated software and controls to precisely maneuver cutting tools.

- Specialized tooling: Custom-designed cutting tools to achieve specific features or finishes.

- Highly skilled machinists:Experienced professionals with a keen eye for detail.

What is the precision of CNC machining?

In general, CNC machining can achieve tolerances of ±0.005 inches (0.127 mm) or better. However, high precision CNC machining can reach tolerances as low as ±0.0005 inches (0.0127 mm).

The precision of CNC machining can vary depending on several factors, including:

- The type of CNC machine: 3-axis machines provide good precision, while 5-axis machines can achieve even tighter tolerances.

- The material being machined: Softer materials like aluminum are generally easier to machine precisely than harder materials like steel.

- The complexity of the part: Simple geometries are easier to machine precisely than intricate features.

Do You Use Precision Machines to Build Custom Metal Parts?

Yes. Precision machines are used to build custom metal parts and are instrumental in today’s subtractive manufacturing process.

Prior to CNC (Computer Numeric Control), there was manual machining, where skilled craftsmen used hand-operated lathes, mills, drills, and other tools to produce parts. This process was slow and required years of experience. Early NC (Numeric Control) systems using punch cards allowed for limited automation — laying the groundwork for modern CNC technology.

Today, CNC precision machining is central to manufacturing across countless industries. Parts in your car, household appliances, surgical instruments, door hinges, valves, and even EV electrical components are manufactured using CNC precision technology.

Though highly detailed and governed by standards such as ISO-9001-2015 and AS9100, the steps remain straightforward:

- Machine Program: A CAD (Computer-Aided Design) model is programmed into the CNC machine via CAM software, generating toolpaths, cutting speeds, and process parameters.

- Material Selection: Metals such as aluminum, steel, titanium, tungsten, stainless steel, and copper alloys are selected based on design and functionality.

-

Machining Process:

- CNC Milling: A rotating spindle with a cutting tool removes material across multiple axes to create complex geometries.

- CNC Turning: The workpiece rotates on an axis while a cutting tool shapes cylindrical features.

- Finishing: Processes like deburring, polishing, or heat treatment add strength, smoothness, or corrosion resistance.

- Quality Control: Precision instruments verify dimensional accuracy, ensuring tolerances meet design requirements.

Examples of instruments include:

- Calipers & Micrometers: For precise length, diameter, and thickness measurements.

- Dial Test Indicators & Gauge Blocks:For runout, alignment, calibration, and flatness checks.

- Machine Probes & Laser Scanners: For automated in-process verification and CAD-to-part comparison.

StenTech and Precision CNC Machining

Custom metal parts are manufactured daily by qualified and experienced CNC machining teams like StenTech. Backed by a long history of innovation in precision manufacturing, StenTech delivers tight-tolerance machining for industries including aerospace, medical devices, defense, energy, oil and gas, pharmaceutical, science, and automotive.

With CNC technology and StenTech’s expertise, you can be assured that advances in these industries will continue to be driven by quality, pride, and workmanship.

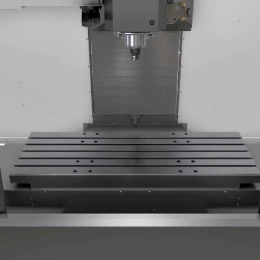

CNC Milling

CNC milling is a subtractive manufacturing process that uses a rotating multi-point cutting tool to precisely remove material from a workpiece, creating the desired shape, dimensions, and surface finish. Guided by advanced computer programming, the milling process can produce highly accurate parts with repeatable results, whether for a single custom prototype or a full-scale production run.

This method excels at producing complex profiles, detailed features, and tight-tolerance surfaces that are difficult or impossible to achieve with manual machining. With the flexibility of multi-axis milling machines, we can machine intricate geometries in fewer setups, improving efficiency and maintaining consistent precision.

CNC milling is often combined with CNC turning in a hybrid process to produce parts with both prismatic and cylindrical features, allowing for more advanced and multifunctional component designs. At StenTech, our milling capabilities are backed by expert programmers and machinists who understand how to maximize accuracy, efficiency, and material utilization for every project.

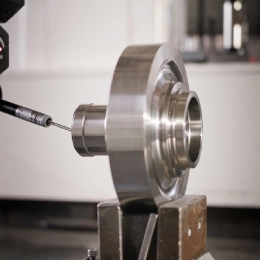

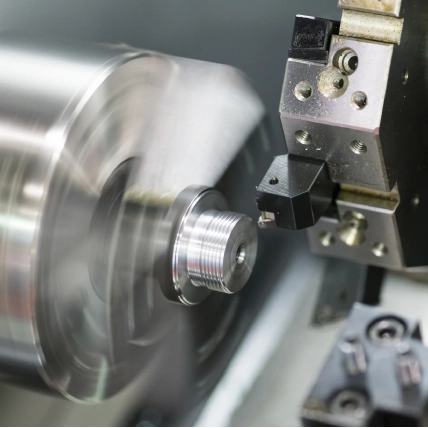

CNC Turning / Lathe

CNC turning is a precision machining process in which the workpiece is rotated at a controlled speed while a cutting tool removes material to achieve the desired shape, dimensions, and surface finish. This method is highly effective for producing accurate, perfectly round components such as shafts, pins, bushings, and threaded parts, and it can accommodate everything from very small diameters to large-scale pieces.

Using advanced CNC lathes, we can create a variety of features, including grooves, tapers, threads, and complex contours, with exceptional repeatability. The process allows for high-speed production while maintaining tight tolerances, making it ideal for industries where consistency and reliability are essential.

For more complex parts, CNC turning is often combined with CNC milling in a multi-process workflow, enabling us to produce components that feature both cylindrical and prismatic elements in a single setup. This hybrid approach minimizes handling, reduces lead time, and ensures every detail is machined with the highest precision.