Stencil Frame Systems

StenTech offers a full range of stencil frame solutions to suit any printing process. We supply all standard frame sizes in both die‑cast and tubular aluminum, as well as two cost‑saving frameless systems that eliminate the need to store multiple frames.

Our patented Mesh Weld process creates a permanent foil‑to‑mesh bond on Standard Tube, Die‑Cast, and Space Saver frames, ensuring durability and consistent performance. With options including Quick Mount Stencils, Space Saver Frames, and traditional Tube & Die‑Cast systems, StenTech provides the flexibility and reliability needed for your unique production requirements.

Large Format Stencils

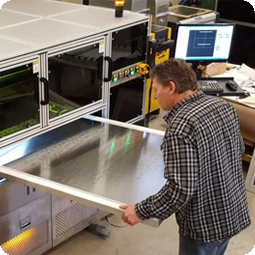

StenTech excels in producing and laser‑cutting large format SMT stencils for applications that demand precision on oversized circuit boards. Designed for PCB assemblers working with expansive panels, these stencils ensure accurate solder paste deposition across even the most complex layouts.

Our large format solutions support advanced industries such as aerospace—where satellites and rockets rely on extensive circuitry—and the growing LED sector, delivering consistent results for high‑density LED arrays. With capabilities up to 46″ × 60″, as well as standard 29″ × 59″ and custom frame sizes, StenTech meets the exacting standards of modern electronics manufacturing.

Equipped with a dedicated large‑format laser system, we’re ready to handle your most demanding stencil projects with precision and quality.

Space Saver Frame

The Space Saver Frame reduces storage needs while retaining traditional stencil mounting. Stretched with polyester mesh, it provides a stable platform for stainless steel stencils and locks securely to an adapter using captured pins and bushings for precise alignment.

This system cuts storage space from 1½″ per stencil to just ½″—three frames fit where one once did. It also prevents damage from shipping loose foils, avoids handling injuries, and offers durable strength to withstand stencil cleaning without concern.

Sizes:

| Frame Description | Inside Dimension | Outside dimension | Thickness |

|---|---|---|---|

| 12x12 spacespacer | 12"x12" | 13 7/8" | 0.50" |

| 15x15 spacespacer | 14.7"x14.7" | 17 3/4" | 0.50" |

| 12x17 spacespacer | 12"x17" | 15"x20 1/8" | 0.50" |

| 23 spacespacer | 23"x23" | 0.50" | |

| 29 spacespacer | 29"x29" | 0.50" |

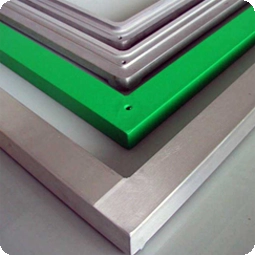

Tubular and Die‑Cast Frames

StenTech offers industry‑standard rigid frames—both tubular aluminum and die‑cast styles—that remain the most widely used solutions for SMT printing. These permanent frames are highly durable, easily reclaimable for future use, and available in a broad range of sizes to suit nearly any application.

For facilities running both leaded and lead‑free processes, we also offer green anodized frames to clearly differentiate stencils dedicated to lead‑free soldering, helping maintain process control and compliance.

Whether you need a rugged solution for high‑volume production or a versatile frame for specialized jobs, our team of BlueRing Stencils experts can guide you in selecting the ideal frame system for your printing requirements.

| Frame Description | Inside Dimension | Outside dimension | Thickness |

|---|---|---|---|

| 5x5 cast | 5"x5" | - | 0.74" |

| 5x7 cast | 5"x7" | - | 0.63" |

| 8x10 cast | 8"x10" | - | 0.74" |

| 12x12 cast | 12"x12" | - | 1.00" |

| 15x15 cast | 15"x15" | - | 1.00" |

| 12x17 cast | 5"x5" | - | 1.00" |

| 20x20 cast | 20"x20" | 23"x23" | 1.00" |

| 23x23 tubular | - | 23"x23" | 1.00" |

| 29x29 tubular | - | 29"x29" | 1.50" |

| Fuji 4000 | - | 22"x31.5" | 1.06" |

| Panasonic/Fuji | - | 21.7"x25.6" | 1.06" |

| 29x59 | - | 29"x29" | 1.50" |

| 19x59 | - | 19"x59" | 1.50" |

| 29x43 | - | 29"x43" | 1.40" |

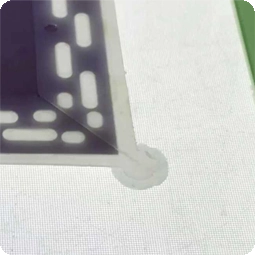

Mesh Weld Bonding

StenTech’s patented Mesh Weld bonding process sets the industry standard for foil‑to‑mesh attachment. Unlike traditional methods that rely on problematic epoxy bonds, Mesh Weld uses a precise combination of pressure, heat, and a durable plastic edging to create a permanent, fail‑safe connection. With hundreds of thousands of stencils in the field and zero recorded de‑bond failures, this process delivers unmatched reliability.

Engineered for today’s demanding SMT environments, Mesh Weld withstands aggressive cleaning methods—including high‑temperature, ultrasonic, and harsh chemical processes—without compromising performance. For more than seven years, StenTech’s Mesh Weld has ensured consistent stencil integrity, minimized process interruptions, and reduced production costs.

VectorGuard® Stencil Mounting System

The VectorGuard® stencil mounting system, developed by DEK, remains one of the most trusted and widely used frameless stencil solutions since its introduction in 2004. This innovative system uses a single reusable frame that allows manufacturers to quickly interchange different stencil foils, reducing setup time and lowering overall stencil costs.

Unlike traditional mesh‑mounted stencils that can lose tension and sag over time, the VectorGuard® system delivers consistent, uniform tension across the stencil surface—maintaining print quality and accuracy even after repeated use. Its design makes it easy to load, unload, clean, and store, while requiring only a fraction of the storage space of conventional framed stencils.

Ideal for high‑mix environments and facilities looking to maximize efficiency, the VectorGuard® system provides reliable performance, cost savings, and long‑term durability in a compact, user‑friendly format.