StenTech SMT Stencil Coatings Engineered for Every Application.

At StenTech, we understand that no two SMT assembly processes are the same. Our range of advanced stencil coatings improves paste transfer efficiency, reduces bridging and cleaning frequency, extends stencil life, and ensures higher yields and consistency across production runs.

Each coating is designed to meet specific customer needs, from maximum performance to cost-effective solutions, while streamlining production and improving overall SMT process reliability.

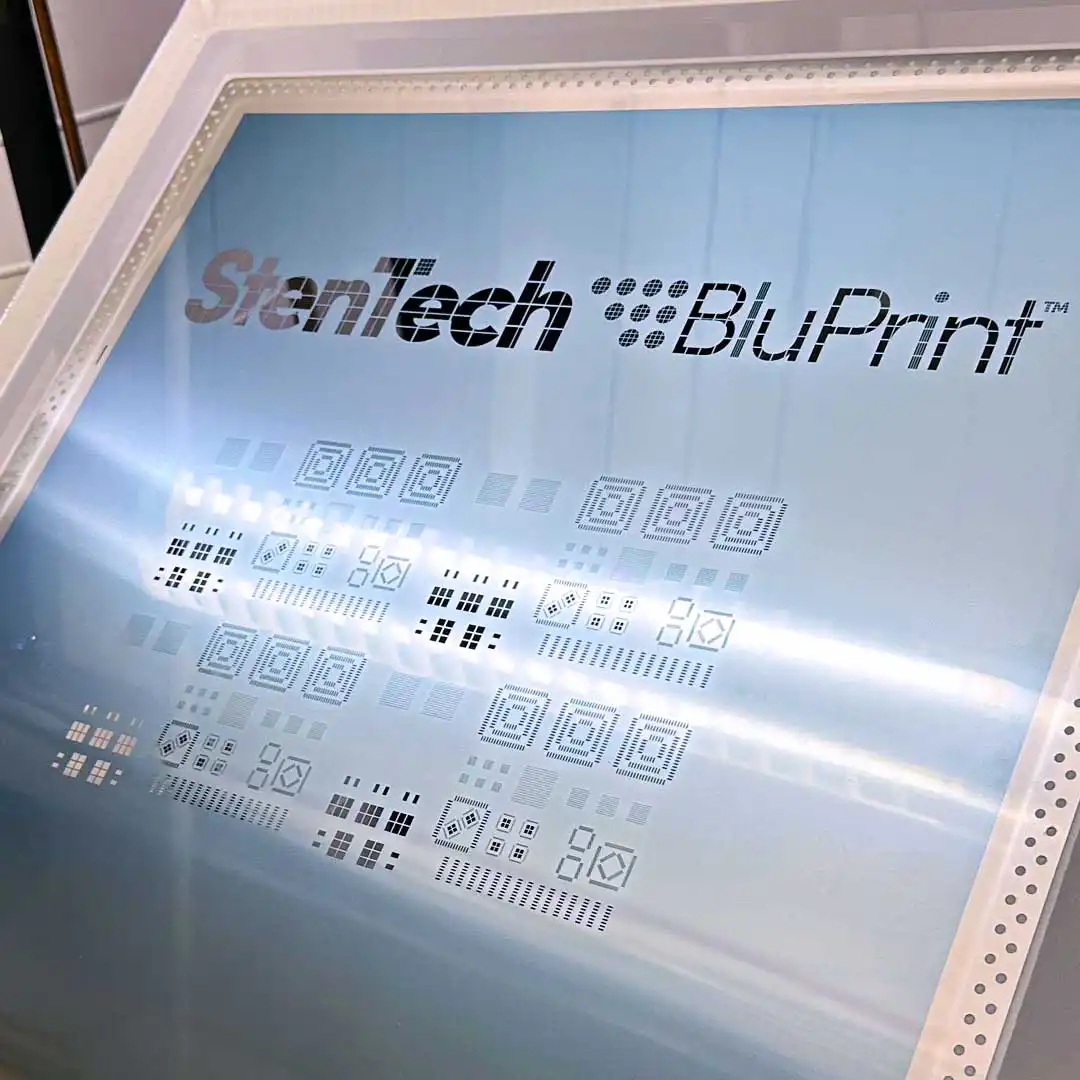

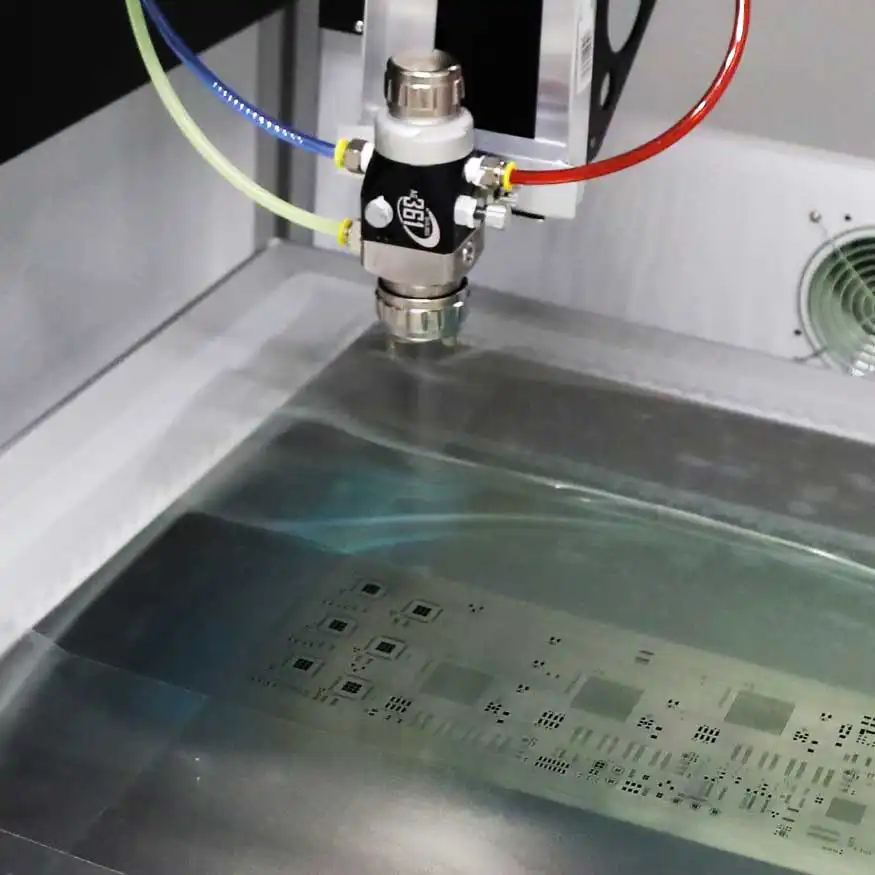

StenTech BluPrint™ PVD: Game-changing Throughput while Reducing Operating Cost

BluPrint™ PVD (Physical Vapor Deposited) is a groundbreaking technology that applies ultra-thin, durable films onto stencil surfaces and aperture walls through a precision-controlled deposition process. This award-winning coating enhances paste release, durability, and consistency, achieving transfer efficiency up to 98% while reducing cleaning cycles by as much as 300%. By extending stencil life, minimizing downtime, and enabling more intricate PCB designs, BluPrint™ ensures reliable performance from the first print to the last, even in high-volume runs.

FULL INFORMATION

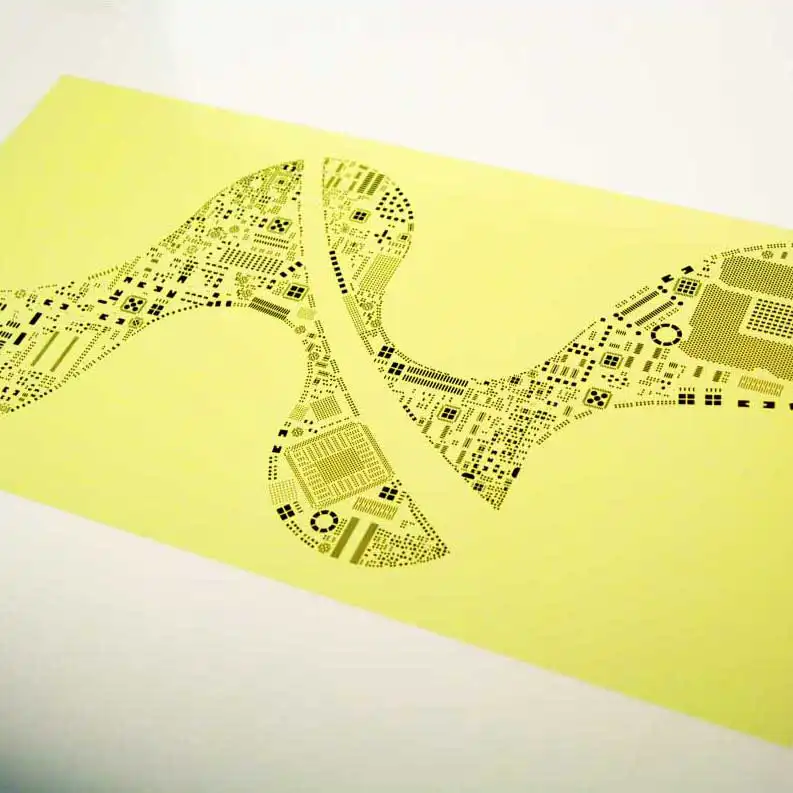

StenTech Advanced Nano™ : Precision Nano Coating with Same-Day Delivery•

StenTech Advanced Nano applies a permanent 1–2 μm hydrophobic layer inside apertures and on the stencil underside, preventing solder flux from sticking and enabling higher paste transfer volumes with improved uniformity. This coating is especially effective on miniaturized or low-area-ratio applications, reducing underside wiping and enhancing contour definition. Designed for efficiency and precision, Advanced Nano stencils are available with same-day delivery, giving manufacturers immediate access to cutting-edge coating technology without production delays.

* Same-day turnaround is available when final files are submitted early and approved. Please note that deadlines may vary by facility.

FULL INFORMATION

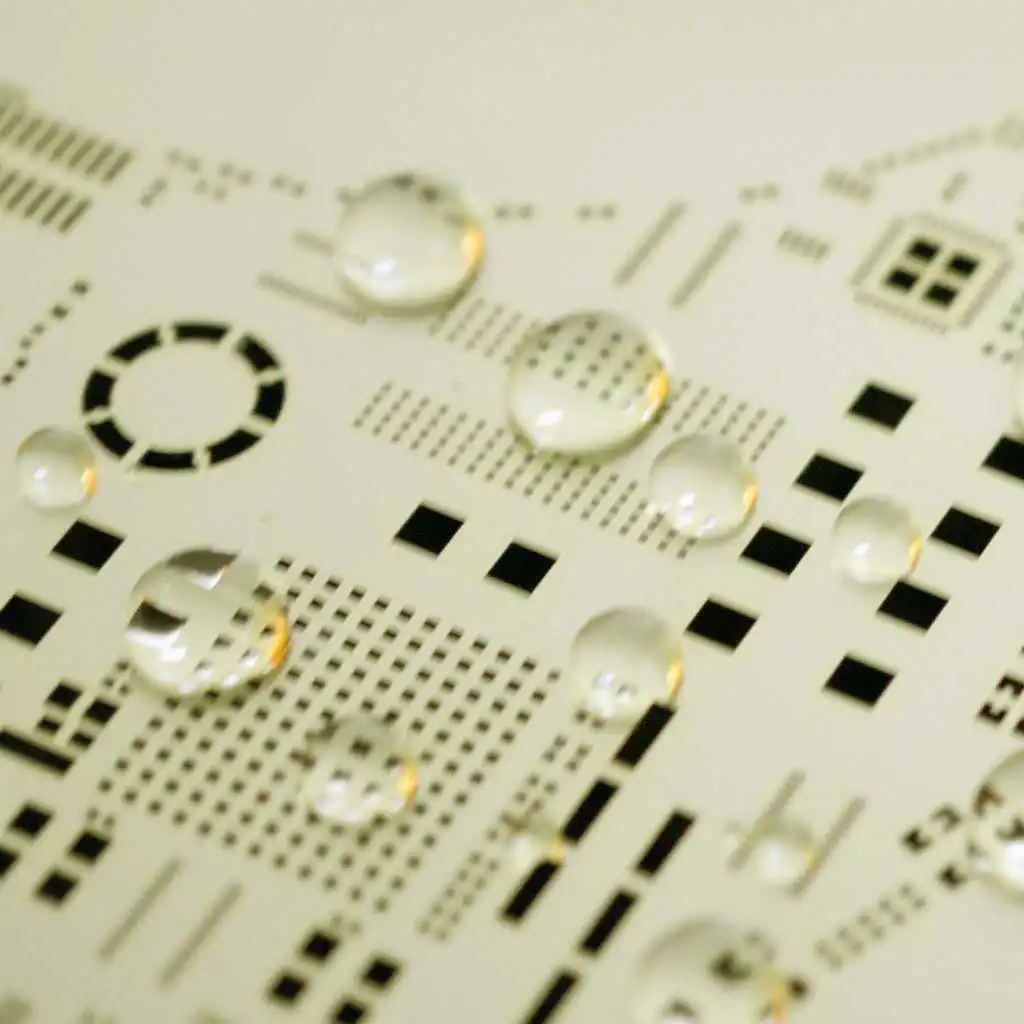

StenTech NanoSlic® Gold: Proven, Production-Tested Nano Technology.

NanoSlic® Gold is one of the industry’s most widely adopted and trusted stencil coatings. Developed from the surface up, its proprietary chemistry is thermally cured and bonded to stencil surfaces and aperture walls, forming a 1–2 μm uniform nano layer that maintains paste transfer efficiency above 97% across thousands of prints. Optimized surface energy reduces solder paste adhesion and bridging, while thermal resistance ensures consistent performance throughout standard SMT reflow processes. As the exclusive licensee in the U.S. and Canada, StenTech provides direct access to this production-tested technology, continuously refined through ongoing R&D in our SMT lab.

FULL INFORMATION

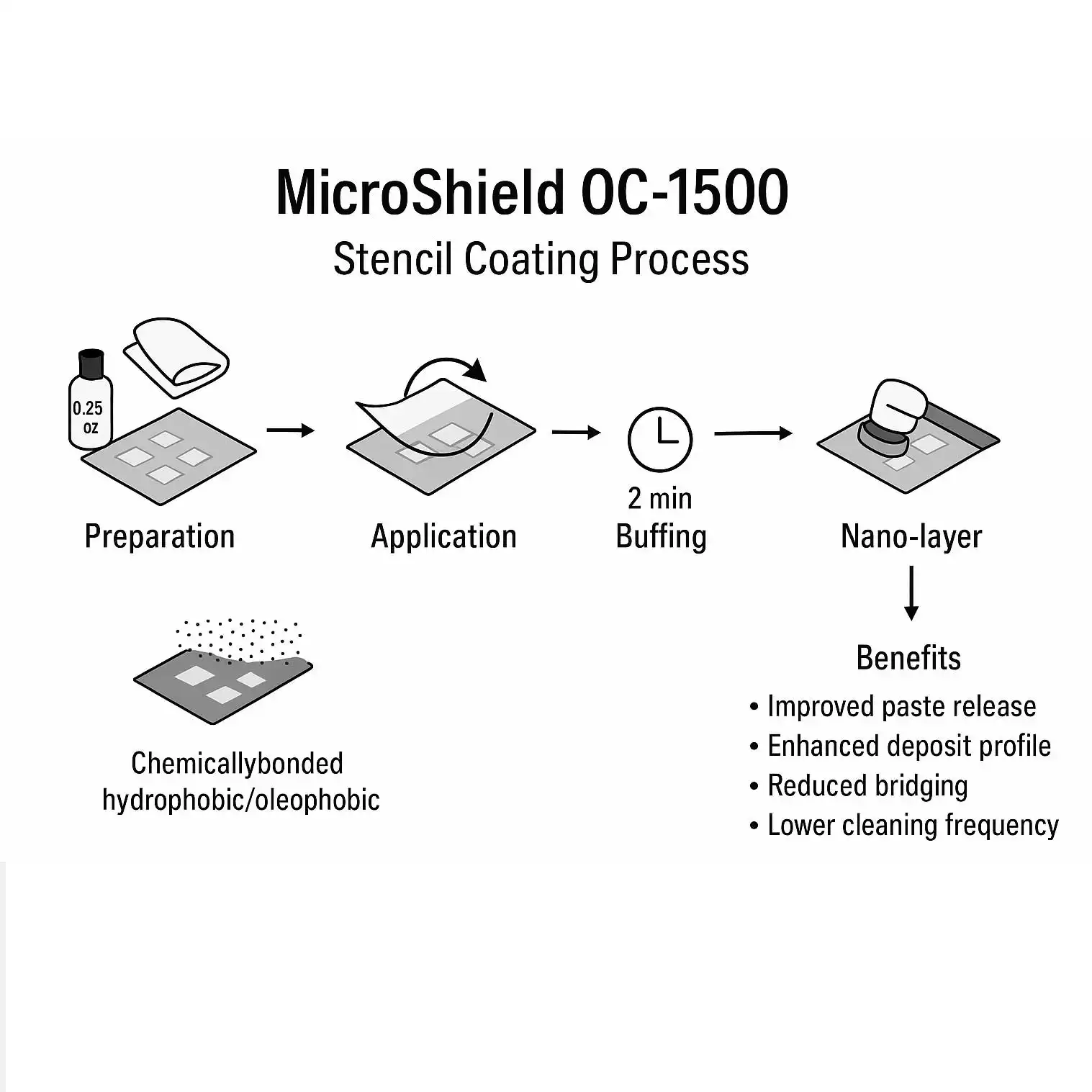

StenTech MicroShield®: Cost-Effective Wipe-On Control for Efficient SMT Production

MicroShield is an on-contact, wipe-on stencil coating designed for small production runs, prototyping, and cost-conscious manufacturing environments.

Unlike conventional treatments that require lengthy preparation or generate excess waste from stencil wipes, MicroShield allows precise, controlled application using its simple wipe-on applicator. This ensures no coating is wasted while maintaining efficient and consistent stencil performance.

Its ease of use, combined with improved paste transfer and reduced cleaning needs, makes MicroShield the ideal solution for manufacturers seeking a practical, cost-effective coating option.

FULL INFORMATION