Step Stencil Technology

Multi‑Level (Step) Stencils from StenTech are designed and manufactured using advanced techniques to enhance stencil printing performance. As mixed technologies on PCBs continue to increase, stepped stencils have become essential for achieving precise solder paste volumes when simple pad‑size adjustments are no longer sufficient.

Relief areas can be precisely milled or etched into the board side of the foil to accommodate rework features, raised labels, or filled vias. These recessed areas allow the stencil to sit flat against the SMT pads, creating a reliable gasket seal that minimizes bridging and reduces the risk of damage to both the board and stencil.

Step‑up regions are produced using StenTech’s patented laser‑weld process, delivering a smooth transition that ensures clean printing and protects the squeegee from wear. Because each stepped stencil requires careful consideration of design and layout, StenTech’s experts are available to guide you in selecting the best technology for your specific process.

- QUICK LINKS

- Welded Steps

- Milled Steps

- Chemically etched Steps

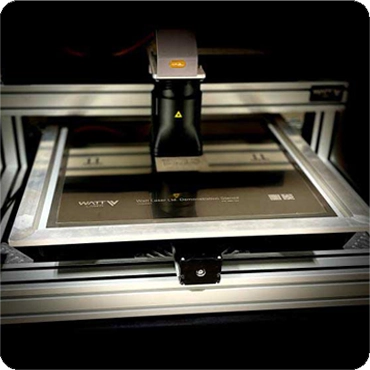

Welded SMT Step Stencils

StenTech’s revolutionary laser‑welded step stencils deliver precise solder paste volumes and consistent brick heights in critical PCB areas. Ideal for mixed technology assemblies, large ground pads, intrusive reflow, or co‑planarity challenges, these additive stencils are built with fine‑grain stainless steel for exceptional accuracy, smooth transitions, and tight tolerances. Our advanced welding process creates stronger, flatter step regions with no surface roughness, enabling faster turn times and reliable, high‑performance printing. For design guidance or step‑area considerations, consult our expert CAD team.

| Step areas | 20 - 150 μm with support for complex shapes |

| Step ramp | Controlled step ramp in 50 μm increments |

| Positional accuracy | < 10 μm on the step areas |

| Material thickness | ± 2% (primary stell and step steel) |

| Board side distortion | Flat with no impact |

| Environmentally friendly | No hazardous chemicals or pollutancts used in process |

| Process | Provides increased control over your print process |

| Thickness | Vary to generate exact paste volume & height for every component |

| Lead-time | Same day quick tuen service available |

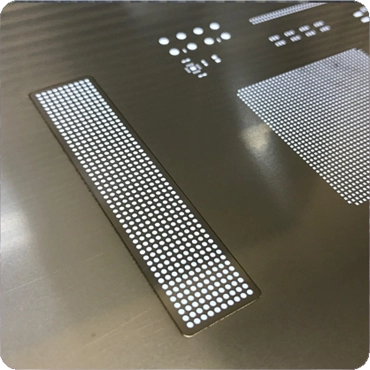

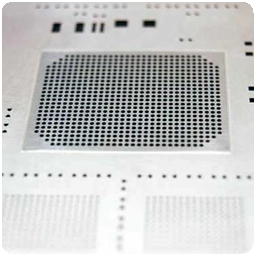

Milled SMT Step Stencils

Milled SMT Step Stencils feature localized variations in foil thickness, enabling precise solder paste volumes for both fine pitch components and larger pads while maintaining optimal deposits on standard parts. Used for decades, stepped stencils have been elevated by modern micro machining technology, delivering Z axis accuracy within ±5 µm, angled step edges, and a burr free finish. The resulting surface roughness (Ra) is less than 0.50 µm—comparable to the original metal—ensuring clean, consistent paste release.

Created through a subtractive milling process, these stencils are ideal for thicker designs requiring exceptional accuracy and tight tolerances. While they come at a higher cost than chemically etched or laser welded alternatives, they provide unmatched precision for demanding applications. For design considerations and best fit guidance, consult our CAD engineering team.

| Process Technology | Micro-Machining | Etching | Welding |

|---|---|---|---|

| Foil Thickness Accuracy | ±5 (0.2 mils) | 127 μm (0.5 mils) | ±2% Foil Thickness |

| Keep Out Zone (Per 1 mil step) | 254 μm (10 mils) | 889 μm (35 mis) | 635 μm (25 mils) |

| Transition | Angled/Steps possible | 90° | Weld bead creates squeegee transition |

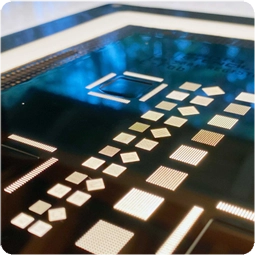

Chemically Etched SMT Step Stencils

Chemically Etched SMT Step Stencils are produced through a subtractive process that removes material from specific areas of the stencil foil. This long‑established technology remains useful for certain applications, particularly coarse board designs or relief etch stencils with multiple pockets, where large or small etched areas are required to create a gasket seal between the stencil and the board.

While chemical etching can deliver fine detail on step islands, its accuracy and tolerances decrease as stencil thickness increases, making it less suited for today’s most demanding designs. For projects requiring the highest precision and tighter tolerances, StenTech recommends considering laser‑welded or micro‑milled step stencils. For guidance on whether chemical etching is right for your process, our CAD engineers are ready to assist.