PCB Assembly Tooling & Fixture Solutions.

At StenTech, we engineer precision tooling solutions that optimize every stage of the PCB assembly process, from the first print to final routing. Our carriers, pallets, and fixtures are meticulously designed to improve handling, enhance placement accuracy, protect delicate components, and maintain process stability through every production step.

Whether it’s securing rigid or flexible circuits, masking during wave solder, supporting boards during screen printing, or ensuring clean separation after assembly, each StenTech fixture is purpose-built for maximum efficiency, repeatability, and long service life. We integrate advanced materials, precision CNC machining, and customer-specific design requirements to create tooling that stands up to the demands of high-volume, high-reliability manufacturing.

Our comprehensive range includes solutions for SMT, wave solder, selective solder, coating, routing, and specialized applications. With capabilities spanning surface mount carriers, flex circuit pallets, vacuum print supports, titanium-insert fixtures, and beyond, we help manufacturers achieve consistent quality, faster changeovers, reduced rework, and lower defect rates, even on the most complex PCB builds.

By combining engineering expertise with hands-on manufacturing experience, StenTech delivers tooling that not only meets technical specifications but also makes your assembly line more productive, reliable, and cost-effective.

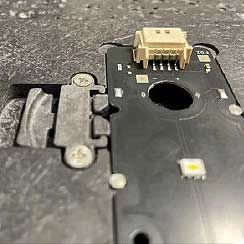

Surface Mount Carriers

In high-volume electronics manufacturing, precision and consistency are everything. Surface Mount Process Carriers are purpose-built to ensure that printed circuit boards (PCBs) remain perfectly aligned and protected through every stage of the assembly process.

Crafted from high-temperature, semi-conductive composite materials, these carriers provide the stability required to handle repeated thermal cycles while maintaining dimensional accuracy. By securing circuit boards from start to finish, they reduce handling errors, improve throughput, and protect delicate components, ultimately driving higher yields and more reliable assemblies.

Flex Circuit Carriers

Flexible and rigid-flex circuits provide valuable design flexibility but require specialized handling to avoid warping or misalignment during assembly. StenTech carriers combine tensioning, compression, precision locating pins, and custom hold-down systems to keep boards flat and secure throughout the process.

This stability ensures accurate component placement, consistent alignment, and repeatable results for these delicate, high-performance designs.

Funky Fixtures

When your assembly needs go beyond standard tooling, StenTech delivers custom-engineered solutions designed for your exact process. Our “Funky Fixtures” are built to solve unique manufacturing challenges — whether that means precision alignment for unconventional board shapes, specialized clamping for delicate components, or thermal masking to protect sensitive areas during soldering and reflow.

We combine advanced machining, creative problem-solving, and in-depth process knowledge to design fixtures that integrate seamlessly into your workflow. No matter how complex or unusual the requirement, we can create a fixture that enhances efficiency, protects quality, and meets the exact demands of your production environment. If your process demands it, we can build it.

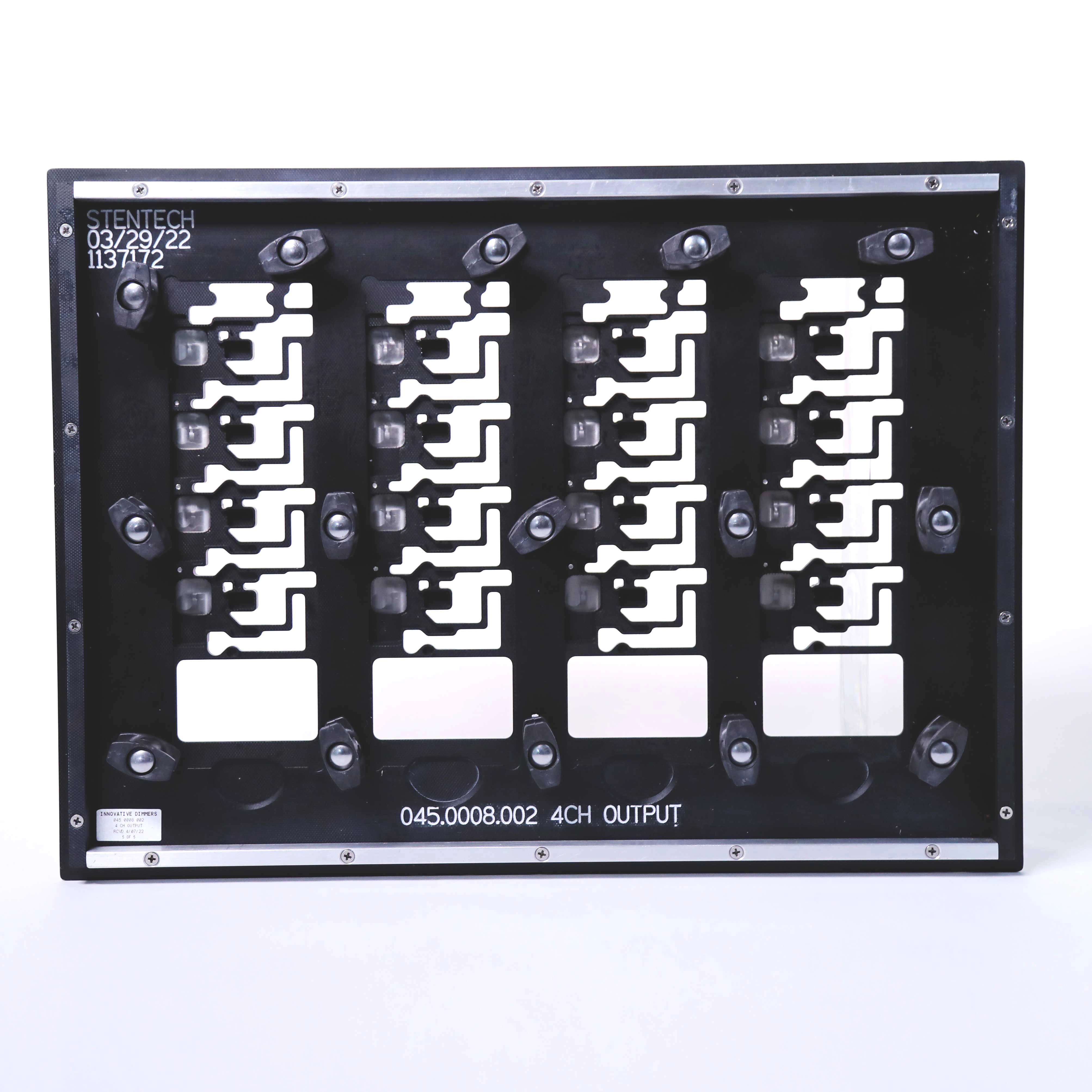

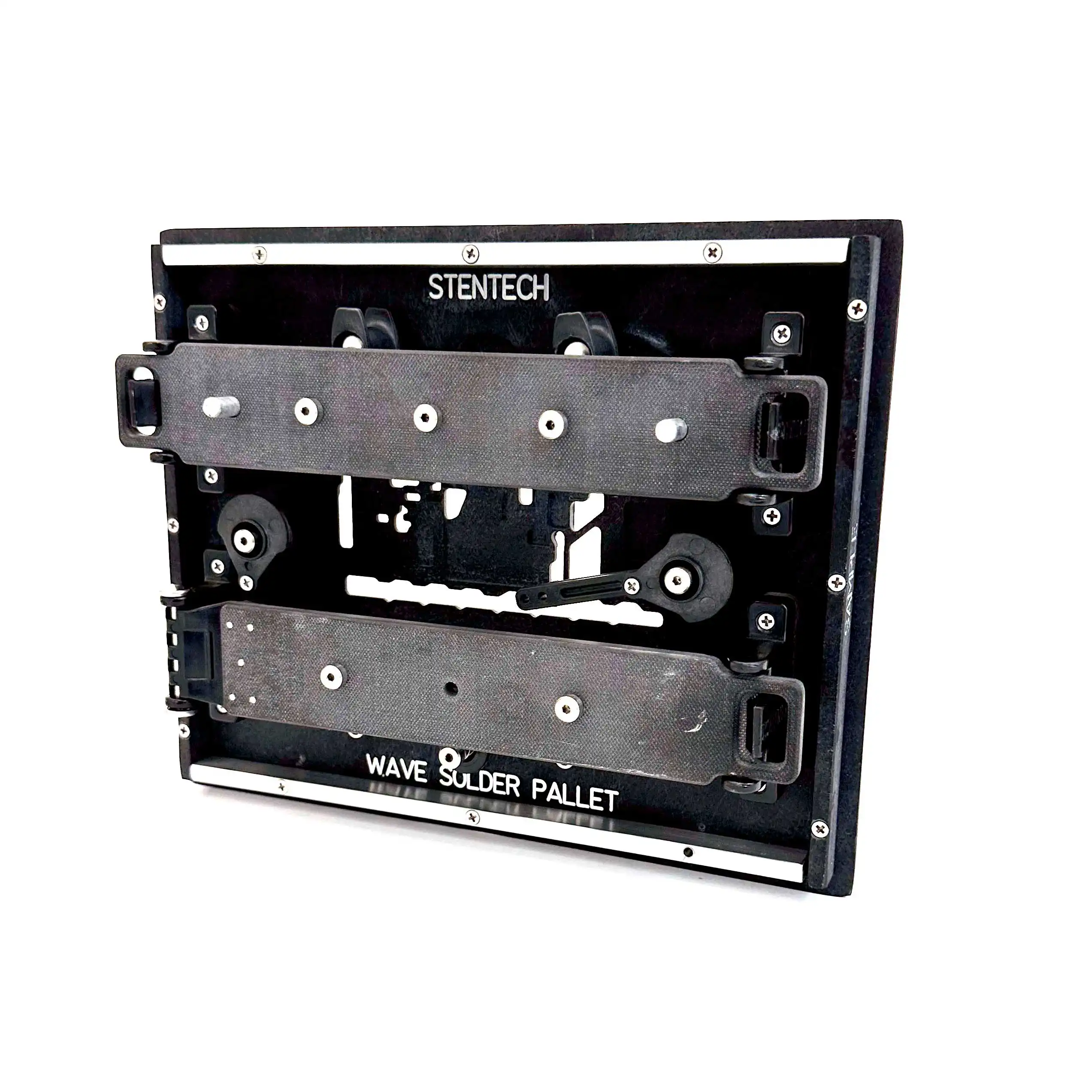

Wave Solder Pallets / Fixtures

StenTech wave solder pallets streamline soldering operations while protecting critical board features. By reducing or eliminating the need for liquid mask or single-use Kapton dots, these pallets provide precise masking for intricate areas, minimizing shadowing, preventing solder bridging, and controlling solder flow.

They shield sensitive features such as gold fingers and connectors, while reinforcing large or fragile arrays that could sag during thermal cycles. This maintains a flat, stable platform for consistent soldering results.

Each pallet is tailored to the board’s geometry and process needs, ensuring secure fit, optimized solder exposure, and repeatable performance. The result is faster processing, improved yield, reduced rework, and lower consumable costs.

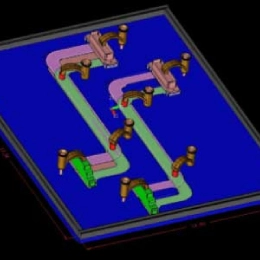

Selective Wave Solder Pallets

StenTech selective wave solder pallets are designed for soldering plated through-hole (PTH) components on mixed-technology assemblies while protecting nearby surface mount devices (SMDs) from heat and solder contact.

Precision-machined with multiple pocket depths and tailored apertures, these pallets accommodate complex layouts and ensure controlled solder flow to PTH leads. Component pockets shield heat-sensitive parts, while sealing walls define solder boundaries for consistent, high-quality joints.

When integrated with PCB designs that follow selective soldering spacing guidelines, these pallets deliver repeatable results, reduce rework, and improve throughput — making them a reliable solution for challenging assembly configurations.

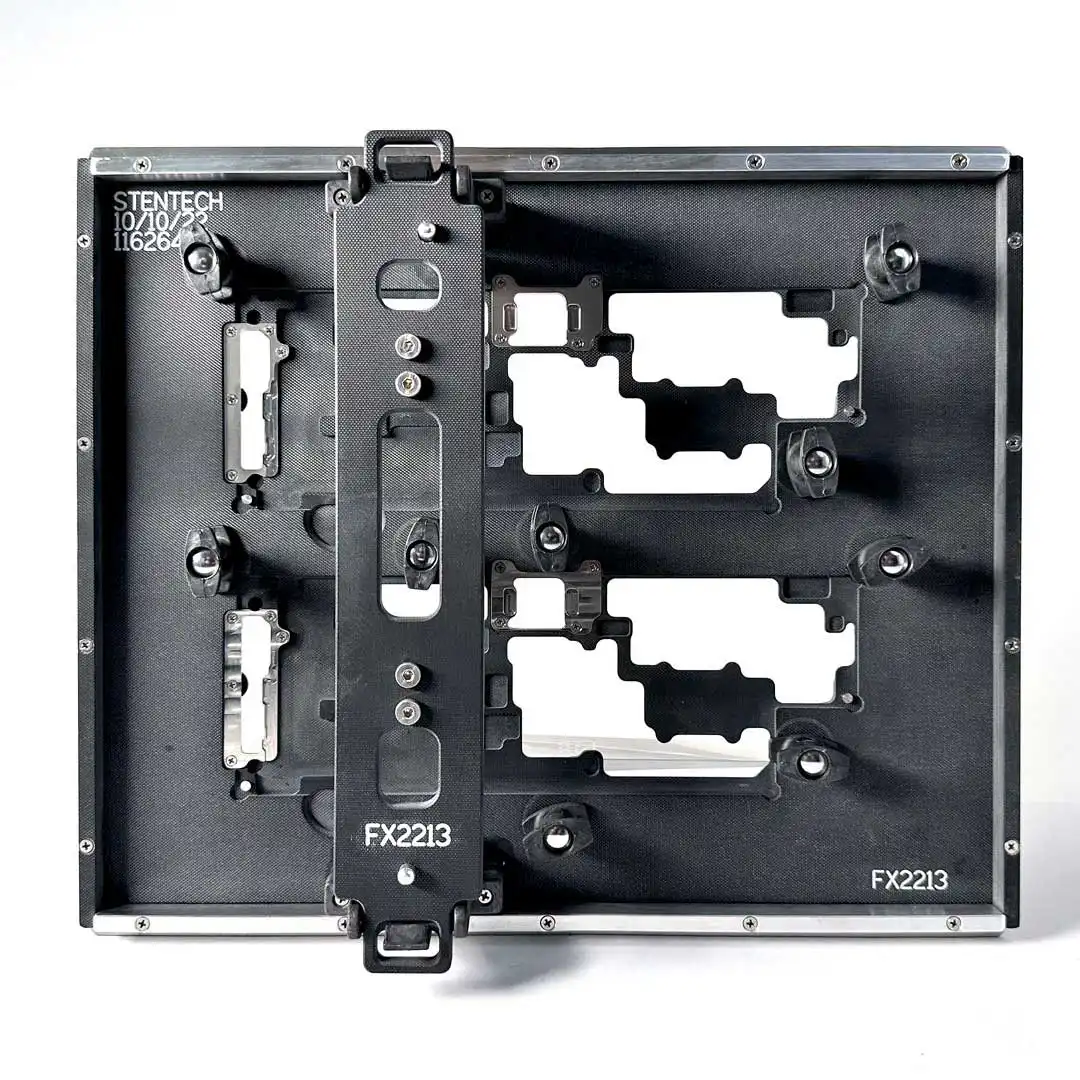

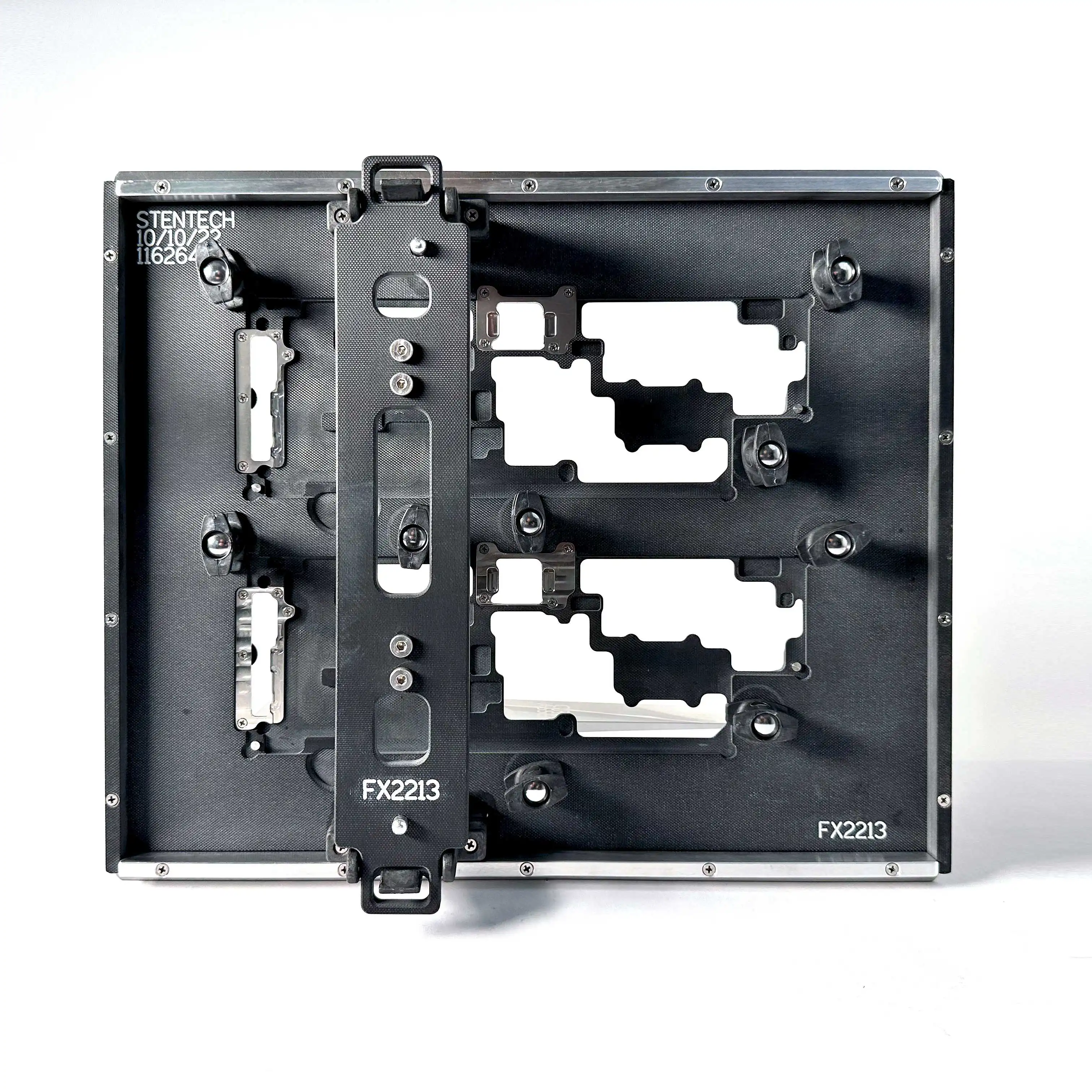

Adjustable Pallets

StenTech adjustable pallets are engineered to simplify production by eliminating the need for conveyor adjustments when processing multiple board sizes through solder, reflow, coating, or wash stages. Their lightweight, low-profile construction applies no undue stress to the PCB, making them ideal for delicate assemblies as well as robust production runs.

Available in configurations for wave solder, conformal coating, AOI inspection, and washing, each pallet is custom-built to your specifications. Adjustable bars and fixtures are designed for quick, tool-free changes, allowing operators to switch between board sizes in minutes. This reduces downtime, increases line flexibility, and keeps production flowing efficiently.

By combining versatility, durability, and ease of use, StenTech adjustable pallets give manufacturers a cost-effective solution for high-mix production environments — ensuring consistent quality and faster throughput without the hassle of constant equipment reconfiguration.

Titanium Inserts

When plated through-hole (PTH) leads are positioned too close to bottom-side surface mount devices (SMDs) for a standard composite sealing wall, titanium inserts provide the strength, precision, and heat resistance needed to maintain process integrity.

Titanium’s rigidity and ability to withstand high temperatures make it ideal for intricate, thin-wall machining in tight-clearance areas. At StenTech, these inserts are integrated into composite pallets only where required, allowing for extremely close spacing without compromising fixture performance.

By combining titanium’s durability with the stability of composite materials, we deliver selective soldering pallets that protect sensitive components, maintain accurate sealing, and perform reliably through repeated thermal cycles — even in challenging, high-density board layouts.

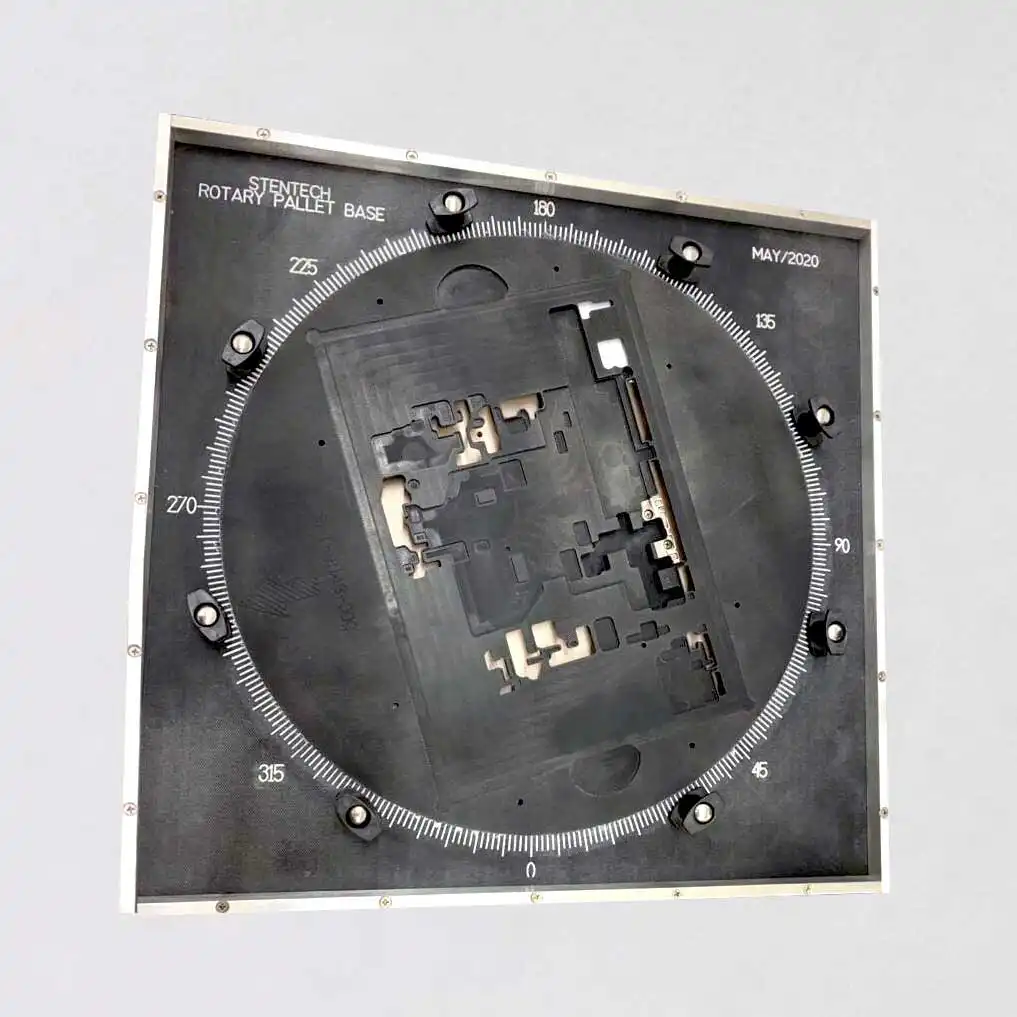

Rotary Wave Solder Pallets

StenTech’s wave solder pallets are designed to precisely mask and protect sensitive areas during soldering while ensuring robust mechanical support for the PCB. Whether for through-hole, mixed technology, or double-sided assemblies, our pallets are tailored to meet your board’s unique requirements.

They are engineered to optimize solder flow, reduce bridging, and improve solder joint quality. High-grade composite materials provide excellent thermal resistance and durability, allowing for long service life and consistent performance over repeated cycles.

By minimizing handling and ensuring accurate solder application, these pallets contribute to higher yields, lower rework costs, and improved manufacturing efficiency.

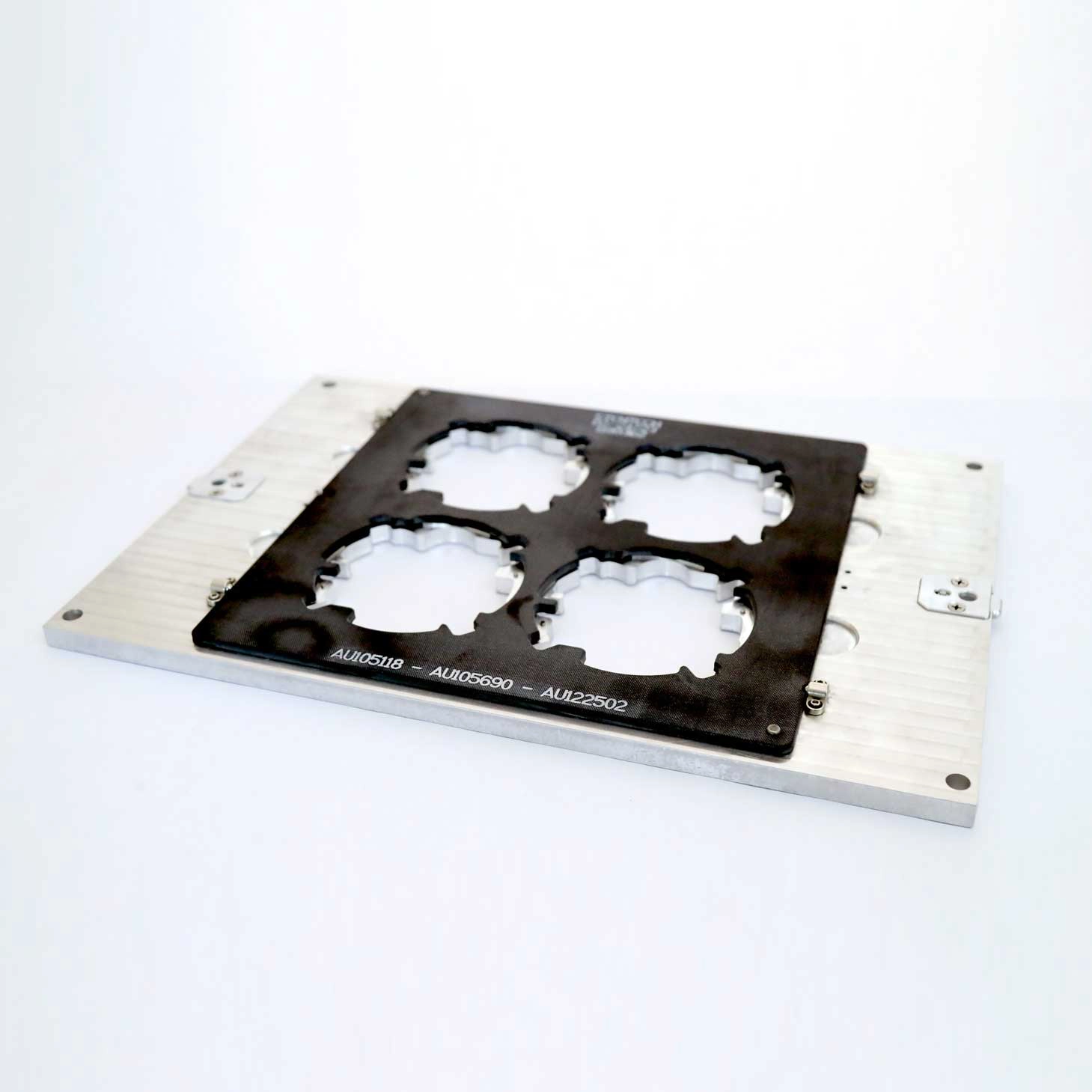

Vacuum Print Support Plates

StenTech’s Vacuum Support Plates are essential for maintaining board integrity during SMT assembly, particularly as designs become more complex and densely populated. They prevent warping, sagging, and bending, ensuring a consistently flat Z- plane, a critical factor for accurate paste deposits and defect-free printing. Custom-engineered to each PCB, these fixtures hold the board securely in place, providing the stability needed for both single- and double-sided assemblies.

Using vacuum plates offers multiple benefits: easy setup, consistent support across production runs, and a measurable reduction in rework, all of which lead to cost savings. As an industry-standard solution for screen printing, dedicated vacuum tooling delivers fast, repeatable setups, minimizes variation, and protects process stability. By eliminating height inconsistencies that can cause hard-to-troubleshoot defects, StenTech ensures that every print cycle meets the high standards demanded in advanced SMT manufacturing.

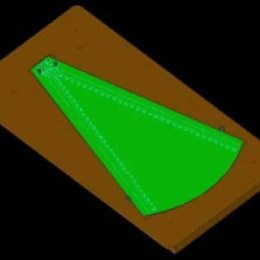

Routing (De-Panelizer) Fixtures

StenTech routing fixtures provide precise and secure support during PCB depaneling, ensuring clean cuts and preventing damage to components. They are custom-built to match the exact outline of your PCB, holding it firmly in place for accurate routing.

Constructed from high-quality materials, these fixtures resist wear and maintain dimensional accuracy over time, even with repeated high-speed cutting operations.

By improving cutting precision and reducing stress on the PCB, our routing fixtures help manufacturers achieve higher throughput, less scrap, and better overall product quality.