Electroform Stencils

StenTech is North America’s foremost authority in electroform stencil technology, delivering advanced solutions for the most complex printing applications in the semiconductor and EMS industries. We specialize in high-precision electroform stencils for paste, flux, ball-drop, wafer bump, epoxy, and 3D applications, offering capabilities and materials not available anywhere else in North America.

With over 25 years of expertise, StenTech is the trusted partner for mission-critical applications where precision, speed, and reliability are essential. Our engineering excellence, unmatched turnaround times, and industry-leading support empower manufacturers to reduce risk, prevent costly delays, and achieve maximum productivity and profitability.

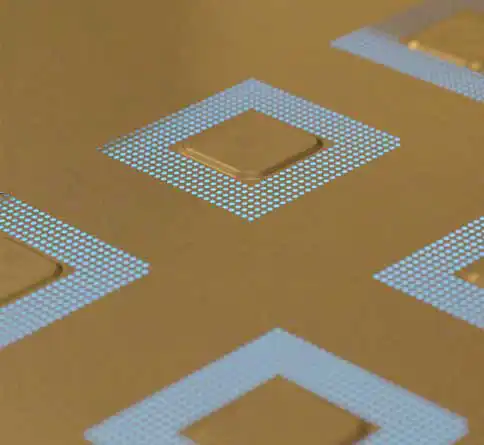

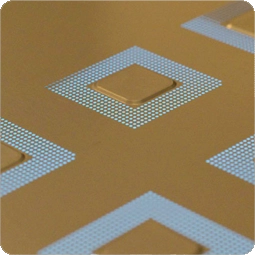

AMTX™ Standard Electroformed Stencils

AMTX Electroforming provides exceptional repeatability and capacity to handle intricate designs. Nickel is grown around photo-resist pillars during the electroform process resulting in mirror-like aperture walls. These extremely smooth walls excel in facilitating the effortless release of solder paste compared to the walls of laser-cut apertures.

- Quick turn for large aperture count.

- Smooth aperture walls promote excellent paste transfer.

- Lower area ratios down to 0.43 have been shown to release solder paste.

- Improved under screen cleaning (USC) performance

- Reduced cleaning frequency.

- Excellent tensile strength and hardness.

- Long stencil life.

AccuScreen Electroform Mesh Stencils

AccuScreen provides a high performance metal mask/screen fabricated using an additive process (Ni). This process is primarily used for printing on flexible electronics with a variety of pastes and inks. Various mesh sizes and wire thicknesses are available with the standard sizes. Additional thickness and screen variation are also possible.

NiEX™ Hard Nickel Electroformed Stencils

NiEX™ electroformed stencils use the same proprietary process with a different material as our market leading AMTX™ stencils. The NiEX™ stencil has a higher Knoop Hardness (HK) than our standard AMTX product for those very thin (1 mil to 3mil) applications such as ultrafine pitch components. Stencil life is greatly improved by the increased hardness of this material. NiEX™ is ideal for ultrafine pitch components including BGAs, QFNs and resistor networks.

Stencil life is greatly improved by the increased hardness of this material. NiEX™ is ideal for ultrafine pitch components, NiEX™ is ideal for ultrafine pitch components including BGAs, QFNs and resistor networks.

NiCut™ Electroformed Stencils w/ laser cut apertures

NiCut™ stencils are our standard Electroform (AMTX) Nickel Stencils with Laser Cut Apertures. These stencils utilize our electroform blank foil material to obtain the smoothest cut from our fiber optic laser system. The applications are similar to the AMTX stencil at a lower cost when the stencil geometries are not as critical.

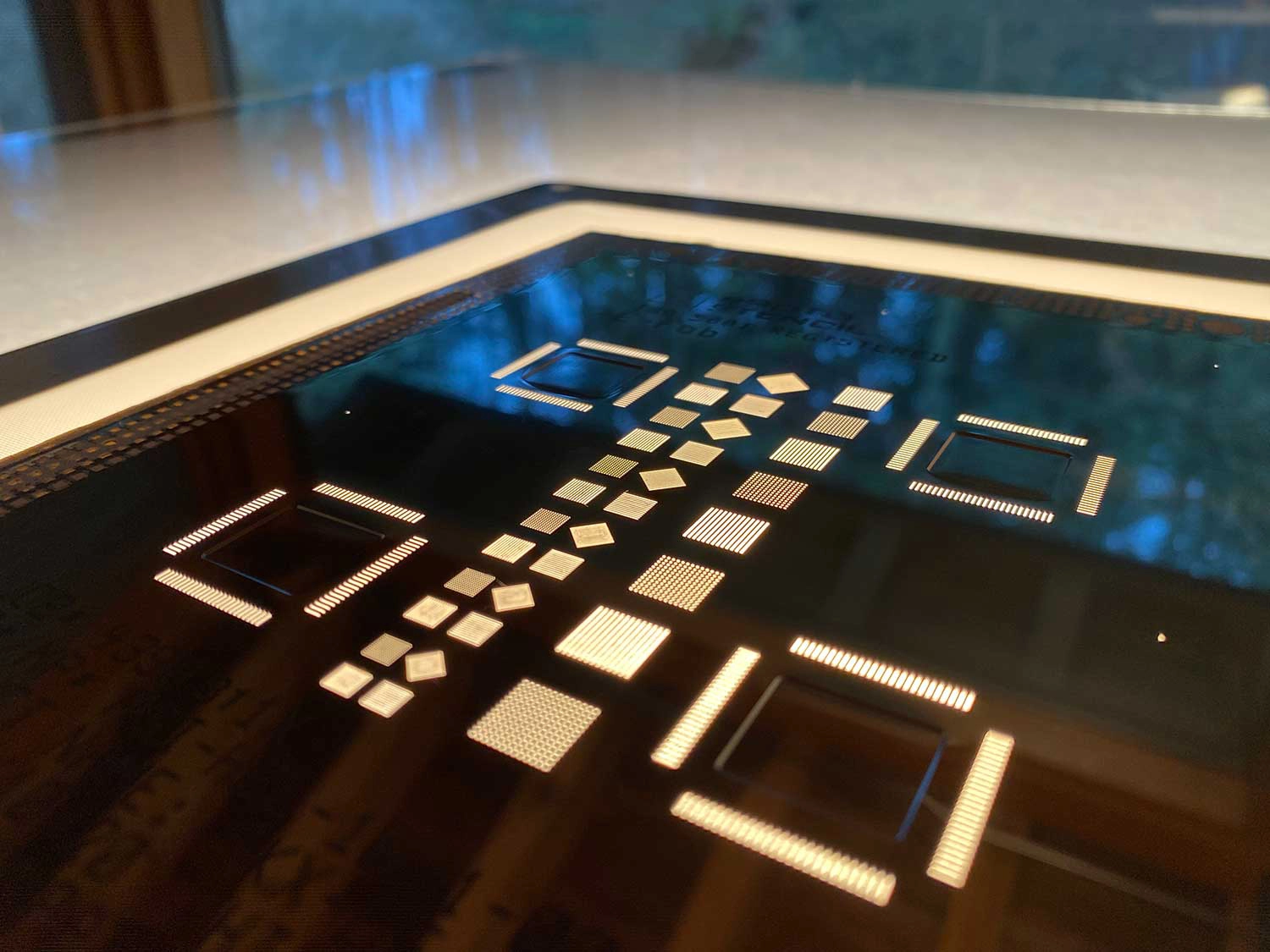

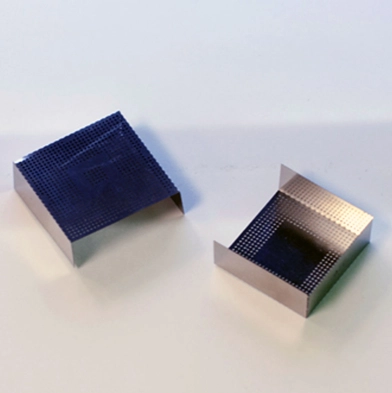

Step Stencils - Electroformed, Laser Cut & Chemical

StenTech's step stencils offer significant flexibility in achieving the proper solder paste height and solder paste volume for the overall paste printing process. Photo Stencil is the pioneer in the field of Step Stencil technology with all processes contained in house for the most comprehensive service available in the industry.

- Available as ‘step up’ and ‘step down’ on the squeegee side and PCB side or on both sides.

- Ideal for providing bar code relief to maintain good gasket during printing.

- Multi-thickness steps available.

3-D Electroformed Stencils

Our 3-D Electroform stencils are ideal for printing on substrate surfaces that have protrusions rising above the print surface. An example of this type protrusion might be a flip-chip device already mounted on the PCB prior to solder paste printing. This is a single thickness electroform stencil, with relief areas not to damage the protruded sections on the board or unit.

A single thickness Electroform Stencil is formed with a raised relief pocket positioned over the protrusion. A squeegee blade with a 25micron slit is ideal for allowing the squeegee blade to raise up over the raised pocket but still be able to print in front of and behind the raised pocket.

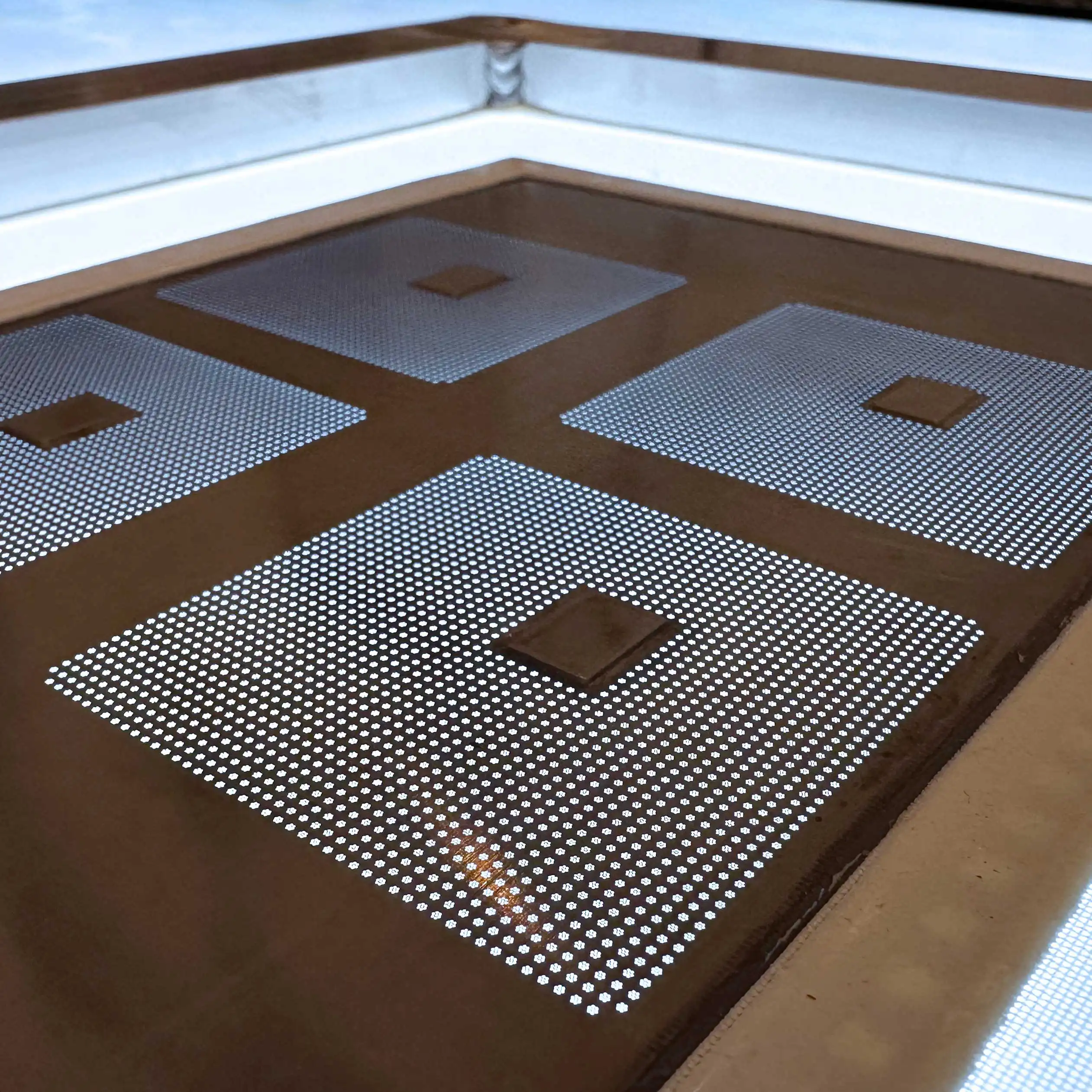

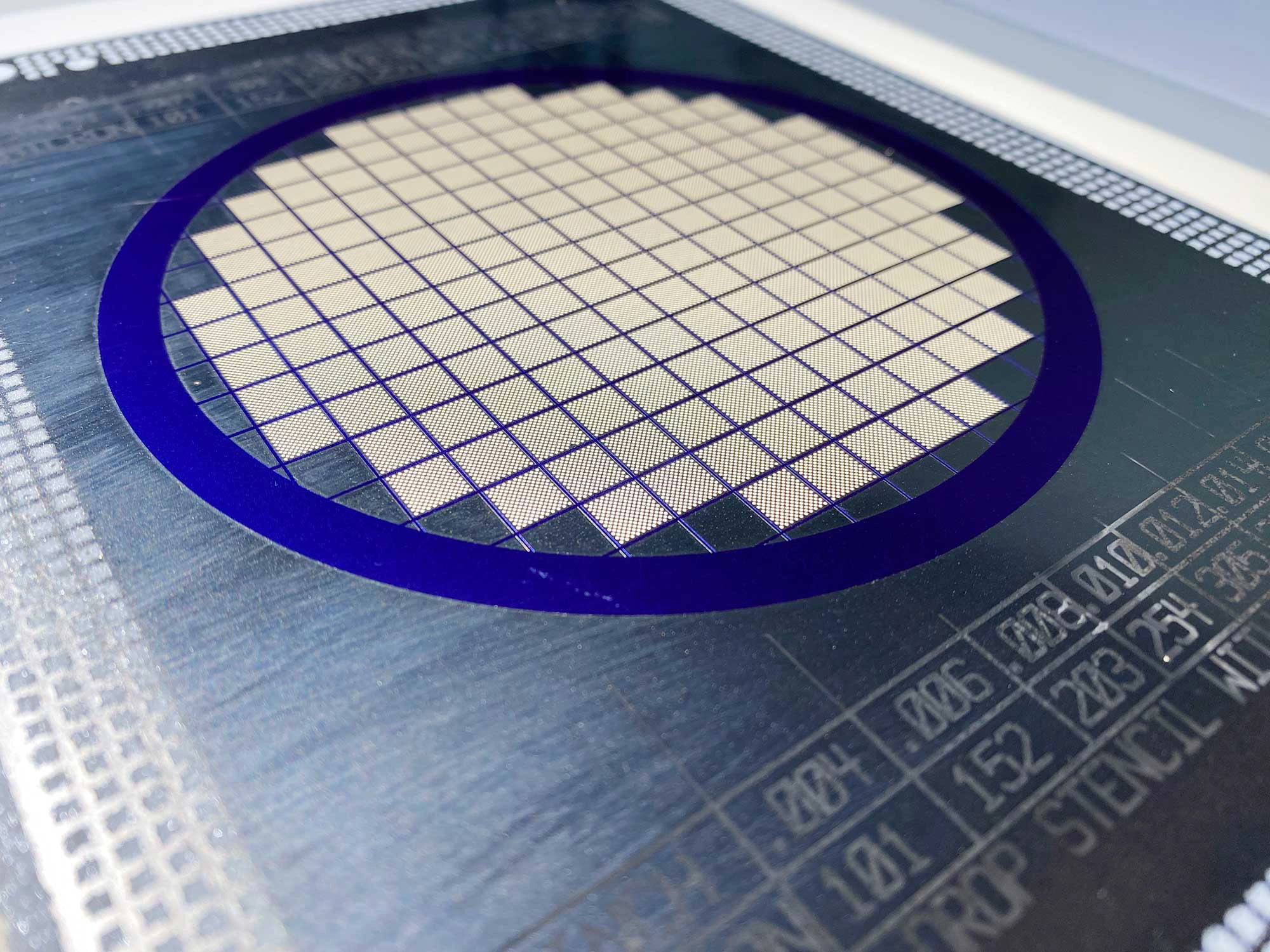

Wafer Bump Stencils

Wafer bumping stencils are electroform stencils used to create bumps on wafer pads. The stencil usually has from 25,000 apertures up to 2,000,000 apertures. Photo Stencil produces two different sets of stencils to achieve this

(a) Paste Print stencil: A print process where solder paste is printed on the die/wafer, the wafer is then re-flowed, melting the solder paste to form truncated spheres (bumps) on the wafer die.

- Useful for bumping of wafers of various sizes and bump count and bump size (<200um).

- Typically used when pitch is at least more than 2 times the bump diameter.

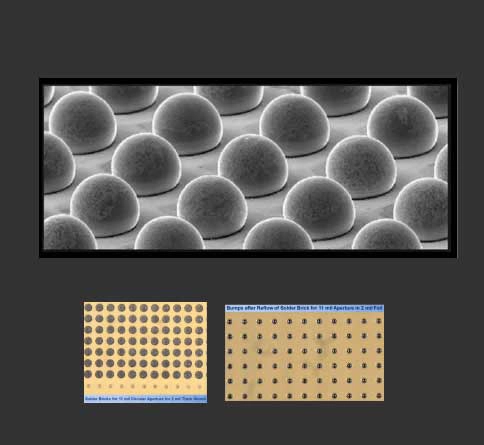

(b) Flux print +Ball Drop Stencils: Set of two stencils.

- Flux is printed on to wafer pads using the first stencil followed by using a wafer ball drop stencil to drop solder balls directly onto the connection pads of a wafer. Since flux is printed onto the wafer pads before the ball is dropped, it has optional relief or standoffs placed on contact side.

- The wafer ball drop stencil is then used to apply solder balls directly onto the flux deposit. Since flux is printed onto the wafer pads before the ball is dropped, the ball drop stencil has standoffs placed on contact side to prevent the ball drop stencil from smearing the printed flux.

- Ball drop stencils are used for a variety of wafer/die sizes, sphere sizes and pad pitches.

- The ball drop process is preferred when the pitch is tighter than 2 times the bump diameter.

- Available as ‘step up’ and ‘step down’ squeegee side, ‘step up’ PCB side or on both sides.

- Ideal for providing bar code relief and thus maintaining the maximum gasket.

- Matched Slit squeegee blades allow for flexure over the raised pocket areas.

- Multi-thickness steps available.

Wafer Ball Drop Stencils

Wafer Ball Drop Stencils are the second stage in the flux-and-ball wafer bumping process. Following flux deposition via a dedicated flux stencil, the ball drop stencil is used to precisely place solder spheres onto the fluxed wafer pads. These electroformed stencils are engineered for tight ball pitch, high alignment accuracy, and minimal variation in ball placement height, all critical for high-yield wafer bumping.

To avoid disturbing the flux layer during alignment and printing, mechanical standoffs or relief features are incorporated on the stencil’s wafer-contact side. These standoffs are created by either laminating a photoresist mask or electroforming a raised nickel rib structure. Both approaches maintain a defined gap, ensuring consistent contact-free operation while supporting high-speed, high-precision ball placement.

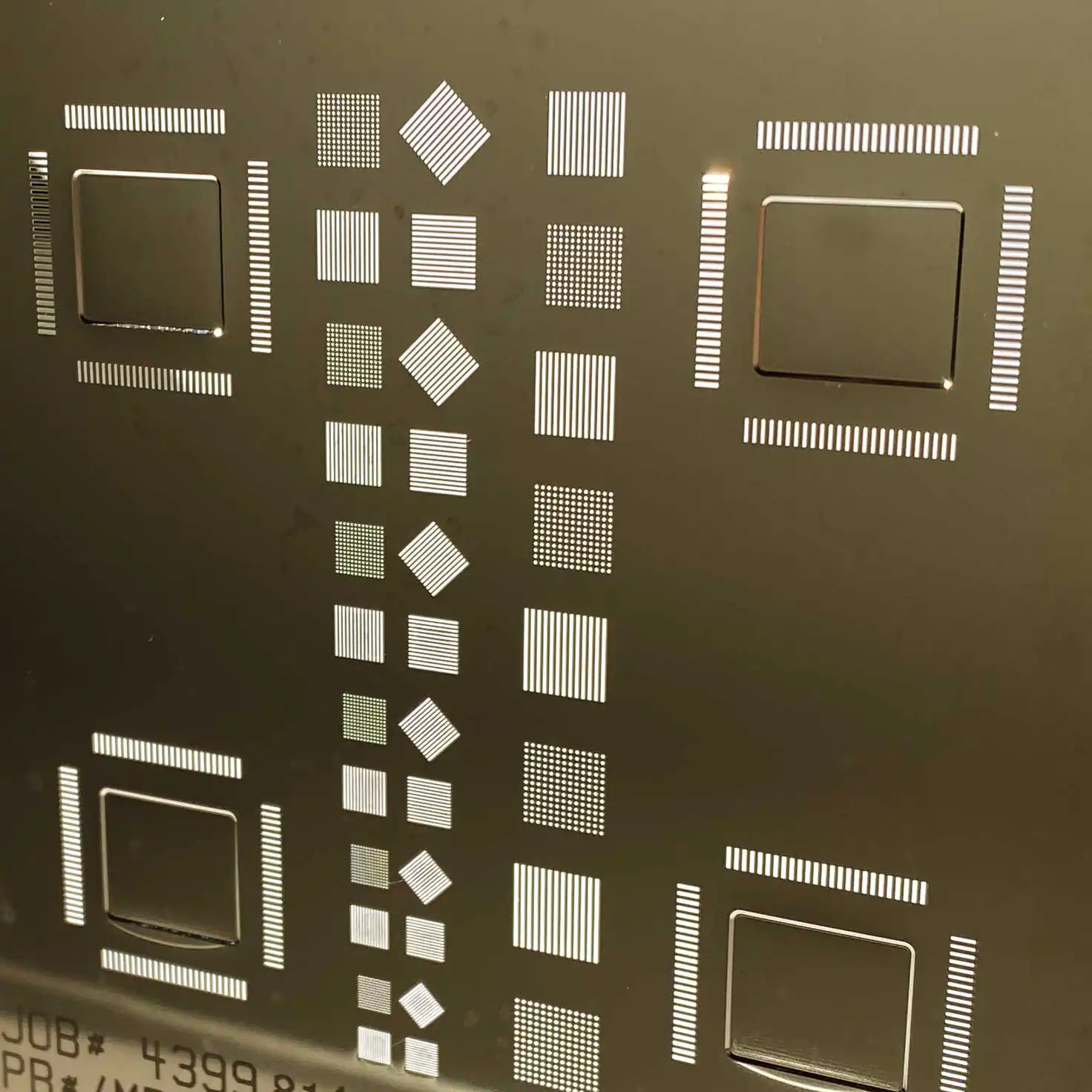

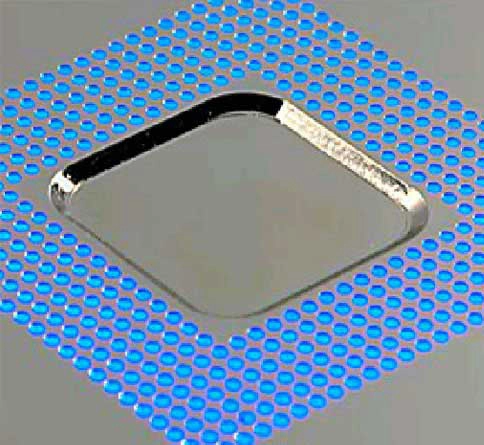

BGA and Component Re-Work Mini Stencils

BGA Rework Mini Stencils are precision-engineered tools designed to deposit solder paste onto individual BGA footprints as well as other components on populated PCBs. Mimicking the original production stencil’s aperture and layout, these mini stencils ensure accurate, repeatable paste placement during component rework. Component print stencils are also available for a variety of rework systems where solder paste is being applied to the component and then placed onto the PCB for reflow. StenTech produces rework stencils from Gerber data or mechanical drawings, supporting a wide range of components including BGAs and others. Designed for both manual rework and dedicated BGA rework systems, the stencils can feature side reinforcements for alignment, front ramps to prevent paste overflow, and custom-fit squeegee blades for each design.

Component print stencils are also available for a variety of rework systems where solder paste is being applied to the component and then placed onto the PCB for reflow.

StenTech produces rework stencils from Gerber data or mechanical drawings, supporting a wide range of components including BGAs and others. Designed for both manual rework and dedicated BGA rework systems, the stencils can feature side reinforcements for alignment, front ramps to prevent paste overflow, and custom-fit.

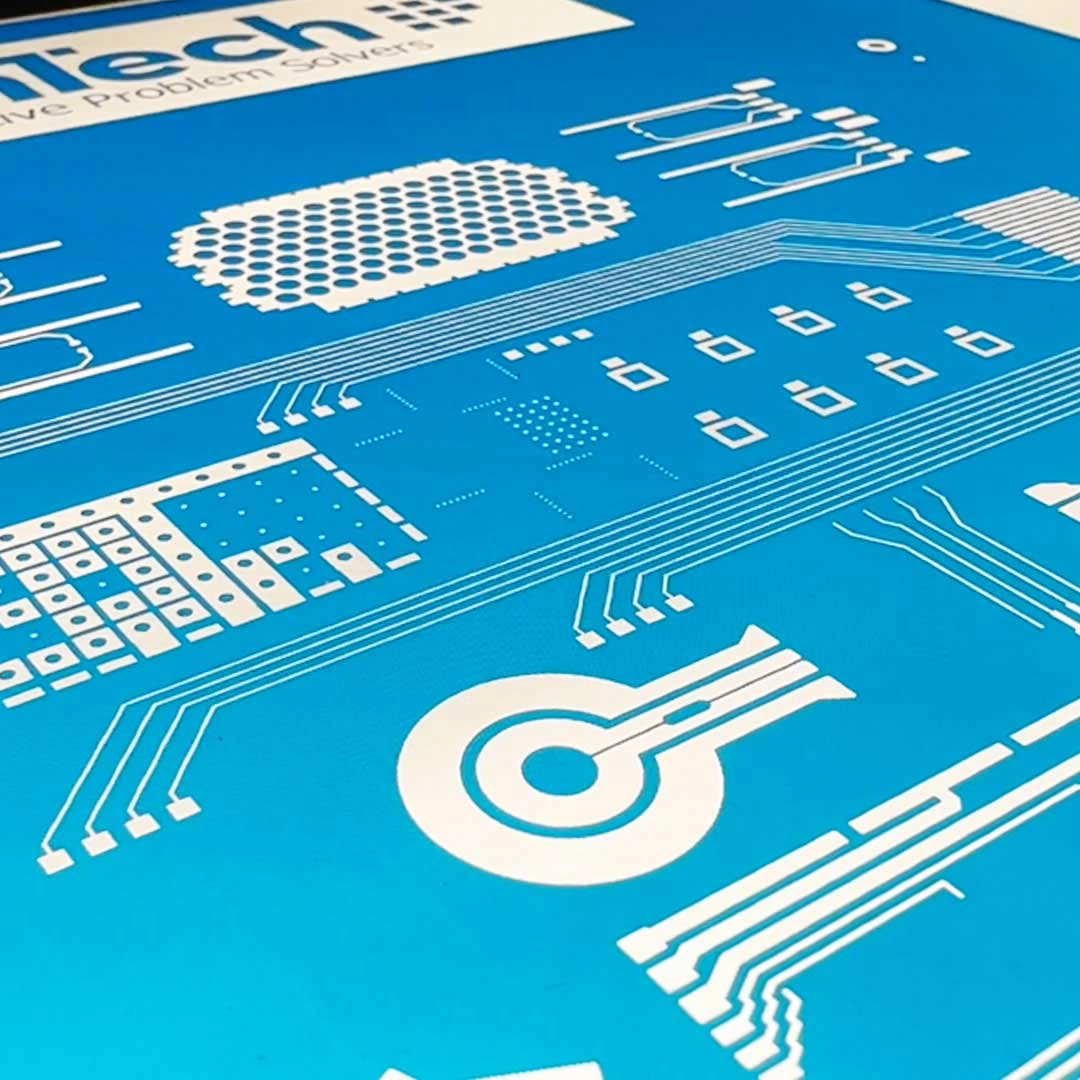

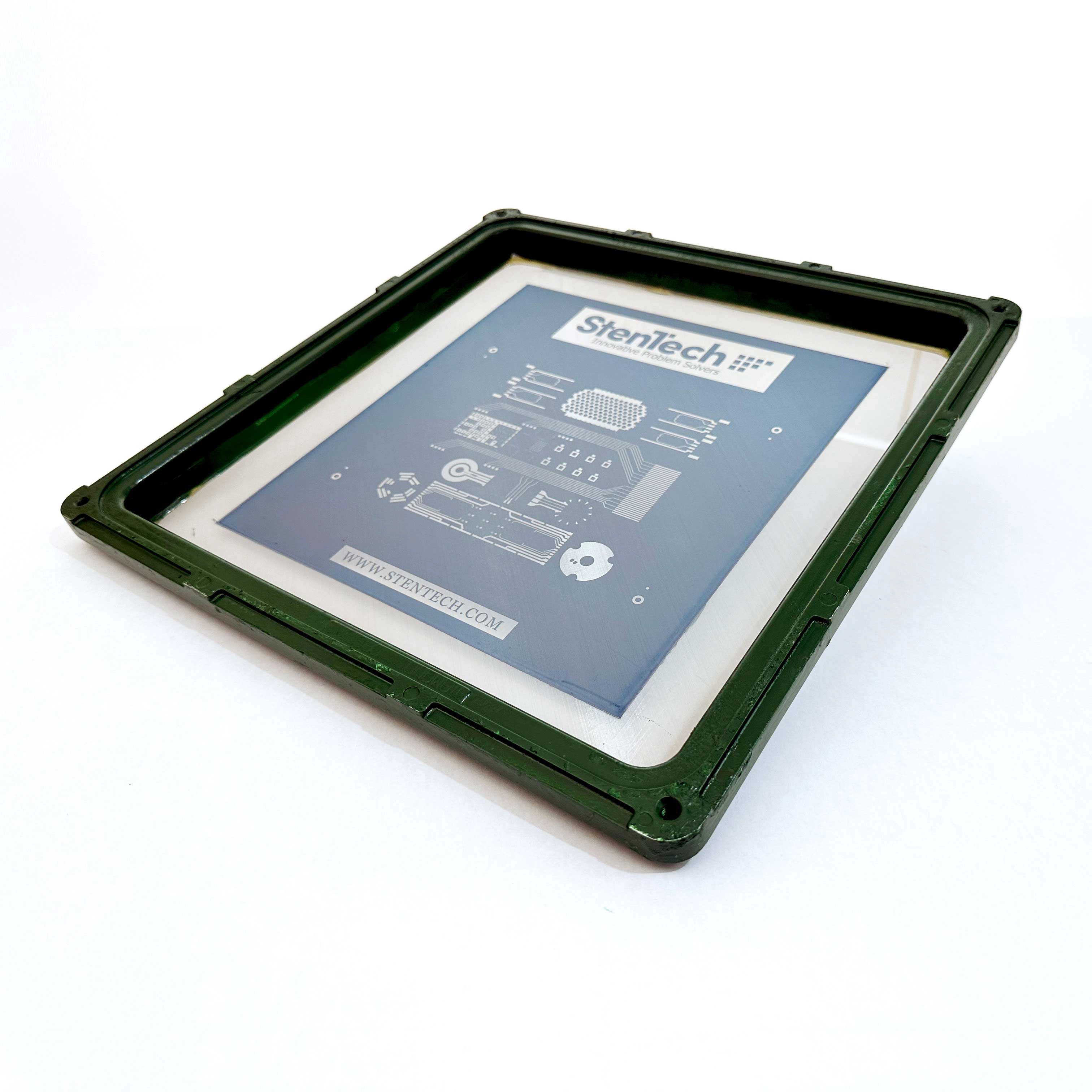

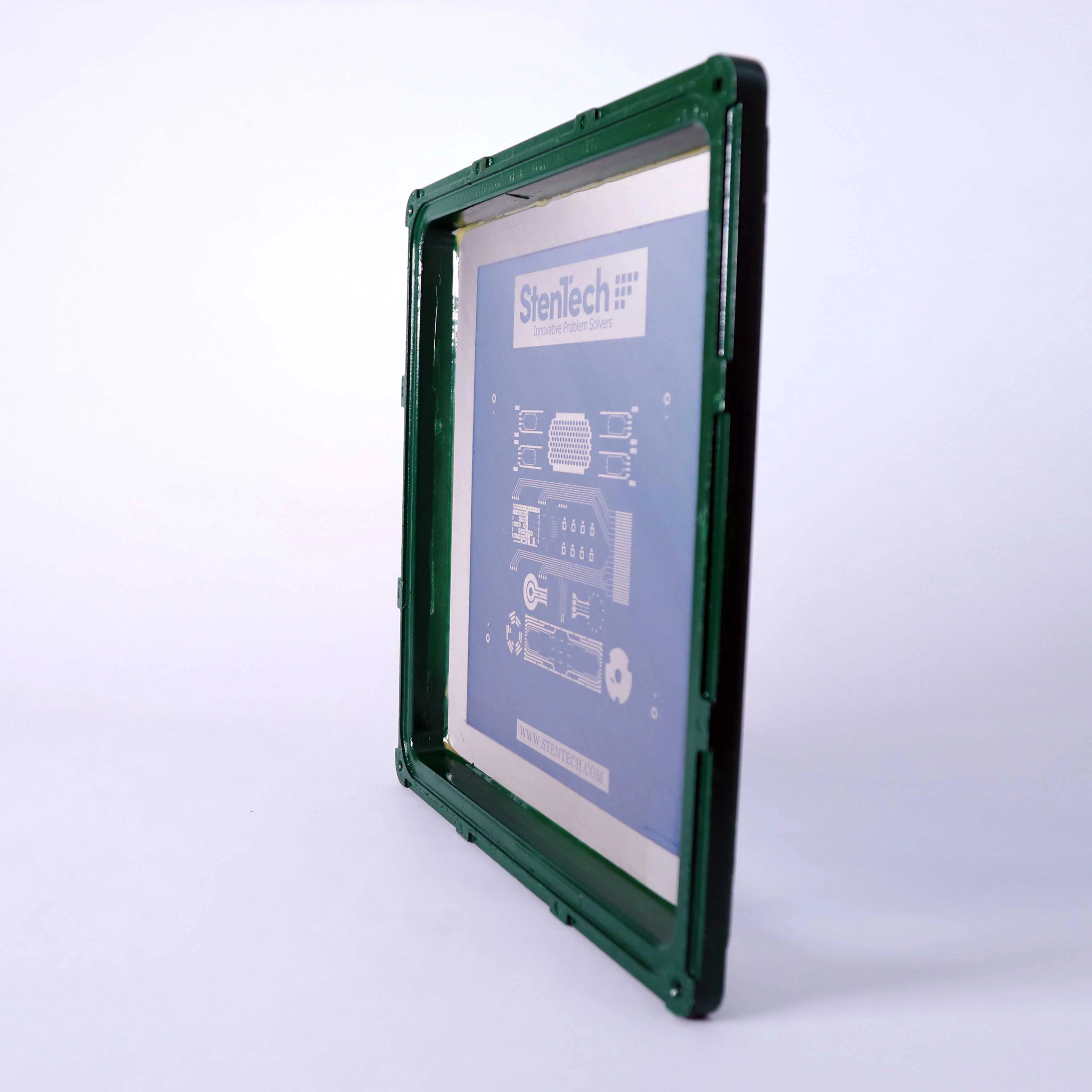

SMT Emulsion Screen Printing

Emulsion screens are among the oldest and most versatile printing methods, still widely used today for their precision and adaptability. The process begins with a frame onto which mesh is stretched and coated with emulsion. The mesh is then imaged, creating a screen ready for printing.

Emulsion screens are essential in industries such as automotive, aerospace, microelectronics, textiles, ceramics, circuit boards, and glass—where accurate deposits and fine line widths are critical. StenTech manufactures screens to meet these exacting specifications and offers a full range of mesh options for every application.

Mesh types vary by weave and thread thickness, with fabrics available in polyester, stainless steel, nickel mesh, and nickel–polyester combinations.