Our Stencils Manufacturing Processes

Built for precision and reliability, StenTech’s manufacturing processes ensure every stencil meets the highest standards of quality. In a fast-paced SMT environment where accuracy and speed are critical, we deliver engineered solutions that reduce defects, optimize performance, and keep production lines running smoothly.

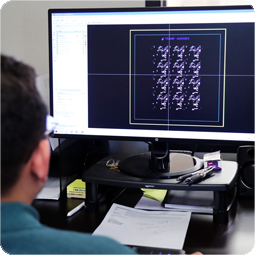

CAD ENGINEERING

Our team of CAD experts provide customers with comprehensive design services. This service includes using our exclusive front-end software tool StenCAD, which automatically examines each assembly’s design by filtering the Gerber file’s D-codes. It ensures that the proposed design achieves the necessary area ratio (AR) for a successful paste deposit.

Laser Cutting

Our facility is equipped with high-speed LPKF 6080 and Tannlin TII laser systems, enabling large-format, high-volume stencil production with exceptional speed and precision. The LPKF’s ultra-light carbon fiber axis ensures fast, accurate motion, while the Tannlin’s integrated design delivers consistent, high-quality results—ideal for meeting the demands of modern SMT applications.

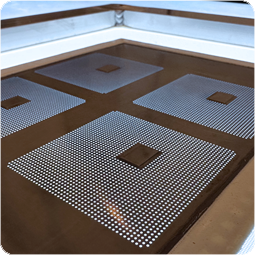

Electroform Imaging & Developing

We've recently upgraded to a state-of-the-art Niva Tech LED Direct Imager, replacing traditional analog film plotting. This system delivers 12 µm resolution and imaging alignment within 3–4 microns—dramatically enhancing quality and consistency.

In addition, we've installed customized IPS Developer/Dryer equipment designed specifically for Photo Stencil. Its vertical track-fed configuration streamlines the development process, delivering faster processing, improved consistency, and superior quality.

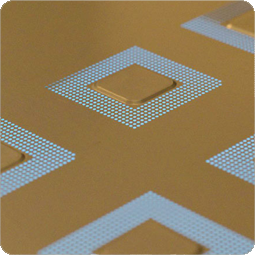

Electroform Chemical Plating & Etching

Our chemical plating center has been fully redesigned to optimize production and improve control over stencil thickness and quality. Equipped with the most advanced technology for chemical-etched stencils, we lead the industry in capability across North America. Both our dedicated plating and etching areas feature state-of-the-art equipment to ensure consistent, high-quality output.

Advanced Coating Technologies

StenTech offers three advanced surface treatments to boost stencil performance and longevity. StenTech Advanced Nano Coating applies a 1–2 μm hydrophobic layer that enhances paste release, improves print yields, and reduces underside wiping—ideal for fine-feature and low area ratio applications. StenTech BluPrint™ PVD Coating offers the same benefits with even greater durability, tripling stencil life for high-run-rate environments. our NanoSlic® Gold coating adds a highly hydrophobic and oleophobic non-stick surface to both the apertures and underside, resisting paste buildup and reducing cleaning cycles. Bonded directly to the aperture walls, it delivers excellent release and durability, even at low SARs.

Quality Control & Delivery

At StenTech, precision is paramount. Our quality control process integrates advanced metrology, aperture scanning, and AOI inspection to ensure every stencil and tooling product meets exacting standards. Using Lupine high-resolution systems, ScanCAD AOI, and our state-of-the-art Micro View non-contact measurement machine, we detect even the smallest defects and verify every layer—including hidden vias—with unmatched accuracy. From nanometer-level thin film measurement to parts over 2.5 meters in length, our tools cover the full spectrum of requirements. Combined with the expertise and craftsmanship of our inspection team, this comprehensive approach guarantees superior quality and reliability in every product we deliver.

And with our ultra-fast, dependable shipping network across North America, you get precision you can trust—delivered exactly when you need it.

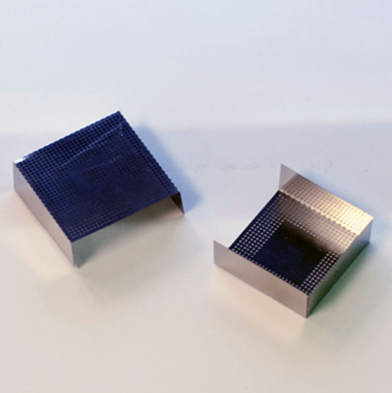

A single thickness Electroform Stencil is formed with a raised relief pocket positioned over the protrusion. A squeegee blade with a 25micron slit is ideal for allowing the squeegee blade to raise up over the raised pocket but still be able to print in front of and behind the raised pocket.